China Metal Sheet Forming Machine Factory - Highway Guardrail Roll Forming Machine – Xinnuo Detail:

Highway Guardrail Roll Forming Machine

Equipment components:made uncoiler, Roll forming machine, computer control system, hydraulic control system,

cutting

Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building

manufacturing, and have features such as nice appearance and durable.

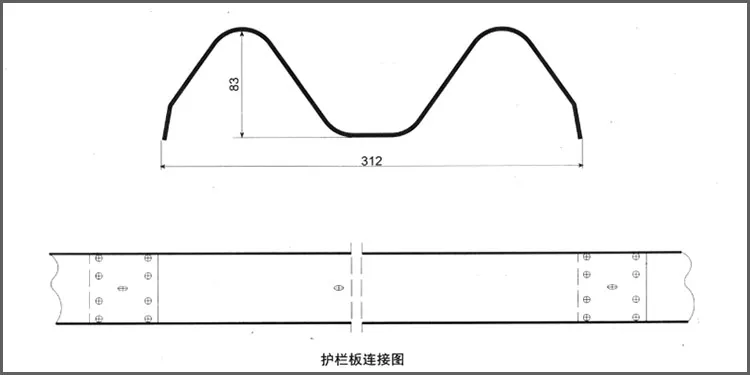

1. Main parameters of highway guardrail machine

| Main parameters of highway guardrail machine | ||

| Suitable to process | Color steel plate, galvanized sheet,aluminum coils and etc. | |

| 2 | Effective width | 310mm |

| 3 | Roller station | 17 rows forming

7 roller leveling |

| 4 | Thickness of feeding material | 2.0-2.5 mm |

| 5 | Productivity | 8-12m/min |

| 6 | Rollers’ material | 45# forging steel |

| 7 | Diameter of shaft | 100mm |

| 8 | Cutting tool material: | GCr12 with quenched treatment 60-62°C |

| 9 | Weight | About 6.9T |

| 10 | Size | 13.5*1.85*1.6mm |

| 11 | Voltage | 380V 50Hz 3phases |

| 12 | Wall thickness of main forming machine | 14mm steel plate |

| 13 | Main forming machine body | 300 mm H steel |

| 14 | Total power | 22+11 kw |

| 15 | Leveling power | 2.2 kw |

2. Processing technique and deployment

Processes: 10T Hydraulic de-coiler—Leveling device–Punching station–Roll forming machine—PLC system—

Hydraulic system-Cutter—Output table

3. Technical Specification

(1)Hydraulic de-coiler: max.capacity: 10T;

(2) Hydraulic System: Power of the oil pump: 11kw Hydraulic oil :40#

(3)Computer control cabinet :

It adopts Delta PLC to control(PLC brand can be changed as your requirement).

The target piece length is adjustable and digit of it can be adjusted

Computed mode has two modes: automatic and manual one.

Processing precision : within 1.00mm

It contains liquid crystal screen, programmer, transformer for the electronic machines and kits of every part.

Reducer is Xingxing Cycloid which works stably and no noise

(4)Counter: One counter gauges length, pulses, and decides length

(5) Output table: It used to load the forming plate

| Packaging Details: | Main machine is nude, the computer control box is packed with wooden frame. |

| Main machine is nude in the container, the computer control box is

packed with wooden packaging. |

|

| Delivery Detail: | 20 days |

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming

machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway

guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines,

shutter slat door forming machines, downpipe machines, gutter machines, etc.

Product detail pictures:

Related Product Guide:

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for China Metal Sheet Forming Machine Factory - Highway Guardrail Roll Forming Machine – Xinnuo, The product will supply to all over the world, such as: Nigeria, Canada, Lesotho, Actually need to any of those objects be of interest to you, make sure you allow us to know. We'll be delighted to present you a quotation on receipt of one's comprehensive specs. We've our individual specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

-

Good User Reputation for National Cold Forming ...

-

Hot Selling for Metal Roof Forming Machine For ...

-

China Corner Forming Machine Pricelist - highw...

-

Hot Sale for Deck Floor Roll Forming Machine -...

-

Best Price on K Span Roll Forming Machine - gl...

-

Wholesale Price Roll Forming - wall panel roll...