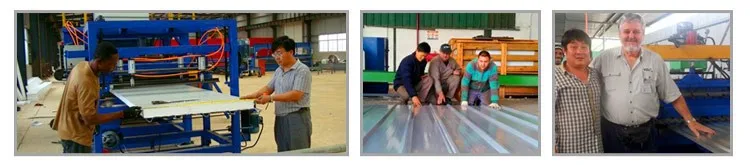

We support our purchasers with ideal premium quality products and substantial level company. Becoming the specialist manufacturer in this sector, we’ve acquired rich practical working experience in producing and managing for China wholesale China Roll-up Door Roll Forming Equipment, We have been in operation for more than 10 years. We are dedicated to quality products and consumer support. We invite you to visit our company for a personalized tour and advanced business guidance.

We support our purchasers with ideal premium quality products and substantial level company. Becoming the specialist manufacturer in this sector, we’ve acquired rich practical working experience in producing and managing for China Roll Forming Machine, Roll Forming, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Allow us to join hands to create a brilliant tomorrow! We are looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to provide you with high quality and efficient services.

garage door roll forming machine

Equipment components:

Man-made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting. Our products

are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and

have features such as nice appearance and durable.

♦Main Parameters:

| Suitable steel plate |

TypeColor steel plateThickness 0.3-1.0mmFeeding width As users needsEffective width As users needs1 Roller station:162 motor power:7.5 kw frequency adjusting speed motor3 width adjust range:380-580mm 4 main machine:350*350H steel 5 Memorial archway: adopts HT200 portal frame6 shaft diameter:diameter 40mm, 40Cr tempering process7 Mould :45 Steel , surface is with hard chrome8 Dimension:5.8*1.6*1.2m

Components:

| No. | Item | Unit | Qty |

| 1 | Manual decoiler | set | 1 |

| 2 | Main roll forming machine | set | 1 |

| 3 | Main machine of composting | set | 1 |

| 4 | PLC control box | set | 1 |

| 5 | Supporter table | set | 1 |

Workflow:

Decoiler–Roll Forming–PLC System–Hydraulic System–Cutting–Transfer Machine–Output Table

Service and Terms

Terms of Payment: 30% of the total contract value paid by T/T as down payment, the rest 70% ofthe total contract

value to be paid by T/T after inspection by buyer in seller’s factory while

before delivery.

Delivery: 30 days after receipt of advance payment

Service: we send technician to your country to fix the machine.The buyer should bear all the

cost including: visa, Roundtrip tickets and suitable accommodation, also buyer should pay salary

80USD/day.

Warranty: 12 months limited warranty

During warranty: parts are free but buyer pay for the shipping fee

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming

machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway

guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines,

shutter slat door forming machines, downpipe machines, gutter machines, etc.

Our machines feature beautiful appearance, long service life, good performance, simple operation, reasonable

price, good quality and so on. Strong technical resources are the most stable guarantee for our products’ quality. We

adopt computer software for design drawing, production drawing and installation drawing for steel construction

equipment. We adopt advanced computer digital inspection and produce high quality light steel structure equipment.

We support our purchasers with ideal premium quality products and substantial level company. Becoming the specialist manufacturer in this sector, we’ve acquired rich practical working experience in producing and managing for China wholesale China Roll-up Door Roll Forming Equipment, We have been in operation for more than 10 years. We are dedicated to quality products and consumer support. We invite you to visit our company for a personalized tour and advanced business guidance.

China wholesale China Roll Forming Machine, Roll Forming, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Allow us to join hands to create a brilliant tomorrow! We are looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to provide you with high quality and efficient services.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.