Trustworthy good quality and excellent credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of “quality first, buyer supreme” for Chinese wholesale Top Quality Color Steel Roof Tiles Roll Forming Making Machine, We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

Trustworthy good quality and excellent credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of “quality first, buyer supreme” for China Steel Frame Roll Forming Machine and Standing Seam Roll Forming Machine for Sale, We will supply much better merchandise with diversified designs and experienced services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

*Detail

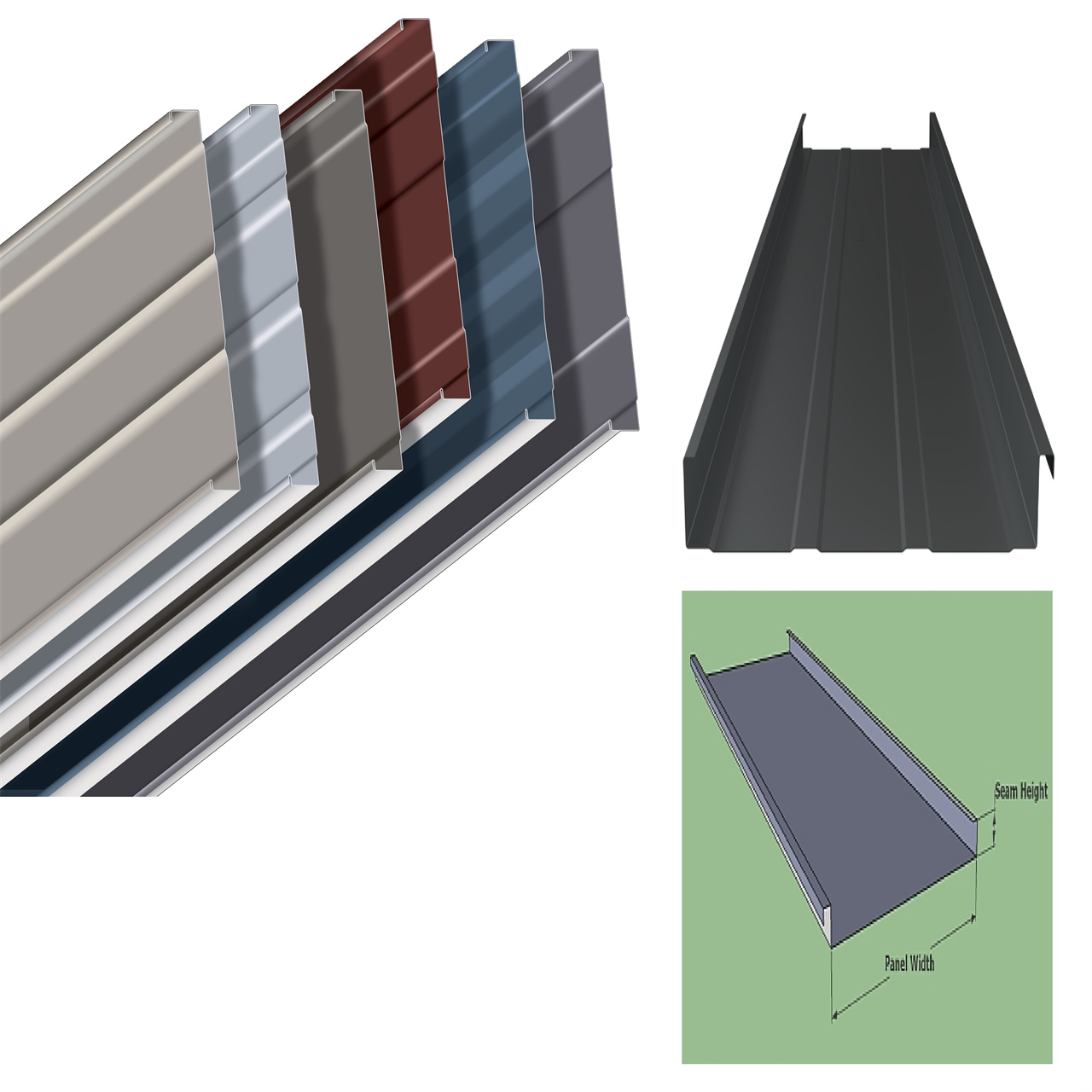

Standing seam panel roll forming machine is one of the major machines we are providing. With this roll former, panels are formed from color steel sheets with cold roll forming technique. The formed panels are widely applied in roof, wall, and other building parts. The cutters of the panel roll former are made from Cr12 molybdenumvanadium steel, showing high hardness and great wear resistance. Near 20 years’ rich manufacturing experience is a powerful guarantee of the quality of the Xinnuo roll forming machines.

Long Span Standing Seam Roof Sheet Cold Roll Forming Machine

Long Span Standing Seam Roof Sheet Cold Roll Forming Machine

The long span standing seam roof sheet cold roll forming machine is a specialized piece of equipment designed to produce long-span standing seam roof sheets. These machines are typically composed of a series of rollers and molds that shape and form metal sheets into the desired roofing configuration. The production process occurs at room temperature, making it known as “cold roll forming”.

Structure and Operating Principle

The machine is typically composed of the following components:

Feeding Mechanism: This mechanism ensures that the metal sheet enters the machine in a controlled and stable manner. It consists of a series of rollers that guide the sheet and maintain its flatness and stability.

Shaping Mold: The core component of the cold roll forming machine, the shaping mold, is made up of a series of molds that are designed according to the desired shape and size of the roof sheet. During the forming process, the metal sheet undergoes bending, pressing, and shearing actions to achieve the desired roofing configuration.

Cooling System: This system is responsible for rapidly cooling the formed roof sheet to maintain its shape and dimensional stability.

Conveying Device: Once the roof sheet is formed and cooled, this device transports it to the designated output location.

The operating principle of the long span standing seam roof sheet cold roll forming machine is based on the plastic deformation of metal sheets. During the forming process, the metal sheet undergoes bending and stretching under the influence of rotating rollers and molds to achieve the desired shape. The entire process takes place at room temperature, making use of the “cold” forming technique.

Characteristics and Advantages

The long span standing seam roof sheet cold roll forming machine possess several characteristics and advantages:

High Precision and Stability: The molds and rollers in these machines are precision-machined and calibrated to ensure accurate and consistent production. Additionally, advanced control systems and sensors are integrated to monitor and control the production process, ensuring stable output.

Efficiency: Long span standing seam roof sheet cold roll forming machines typically operate in a continuous production mode, enabling high-volume production of roof sheets with efficiency. This efficient production approach significantly increases productivity and reduces production costs.

Flexibility: These machines can accommodate different types, thicknesses, and sizes of metal sheets, allowing for flexible production of different roofing configurations. This flexibility offers tremendous versatility in meeting market demands.

Environmental Friendliness: Operating at room temperature, these machines do not require extensive heating or cooling equipment, resulting in reduced energy consumption and environmental impact. Additionally, recycled metal sheets can be used for production, further minimizing resource waste and environmental impact.

Automation and Intelligence: Modern long span standing seam roof sheet cold roll forming machines are often equipped with advanced automation and intelligent systems that enable automated operation and control, reducing manual intervention and operational costs. These systems can either follow preset programs or make real-time adjustments based on feedback to maintain production quality and efficiency.

Reliability: Machines are made from high-quality materials and components, undergone rigorous quality control checks, resulting in reliable and durable machines. Additionally, these machines are equipped with fault detection and alarm systems that can detect and rectify potential issues in real-time, ensuring uninterrupted production operations.

Wide application: Long span standing seam roof sheet cold roll forming machines have found widely used in various industries such as construction, automotive, aerospace, etc. For example, they can be used to produce metal sheet products for car roofs, car doors, etc.; they can also be used to produce aircraft fuselage, airframe components, etc. The versatility of these machines makes them highly sought-after in different industries.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

-

High Quality Automatic Die Cutting and Embossin...

-

High Quality Kexinda Z-Lock Sandwich Panel Prod...

-

Cheapest Price Good Quality Metal W Plate Makin...

-

Factory Price For China FRP Roofing Sheets Maki...

-

Factory Directly supply S235 S355 Ss400 A36 A28...

-

High Quality for China Solar Panel Aluminum PV ...