Discover the Power of Precision with the Xinnuo Rib Panel Roll Forming Machine,

Box rib, Master rib panel, PIR PBR panel, Roll Forming Machine,

|

NO.

|

Main parameter of Botou city canton fair authentication 828 automatoc press blue making glazed joists steel roof tile roll froming machine with ce

|

|

|

1

|

Suitable to process

|

Color steel plate

|

|

2

|

Width of the plate

|

1000mm

|

|

3

|

Thickness of the plate

|

0.3-0.7mm

|

|

4

|

De-coiler

|

Manual one, can load 5 tons raw material

|

|

5

|

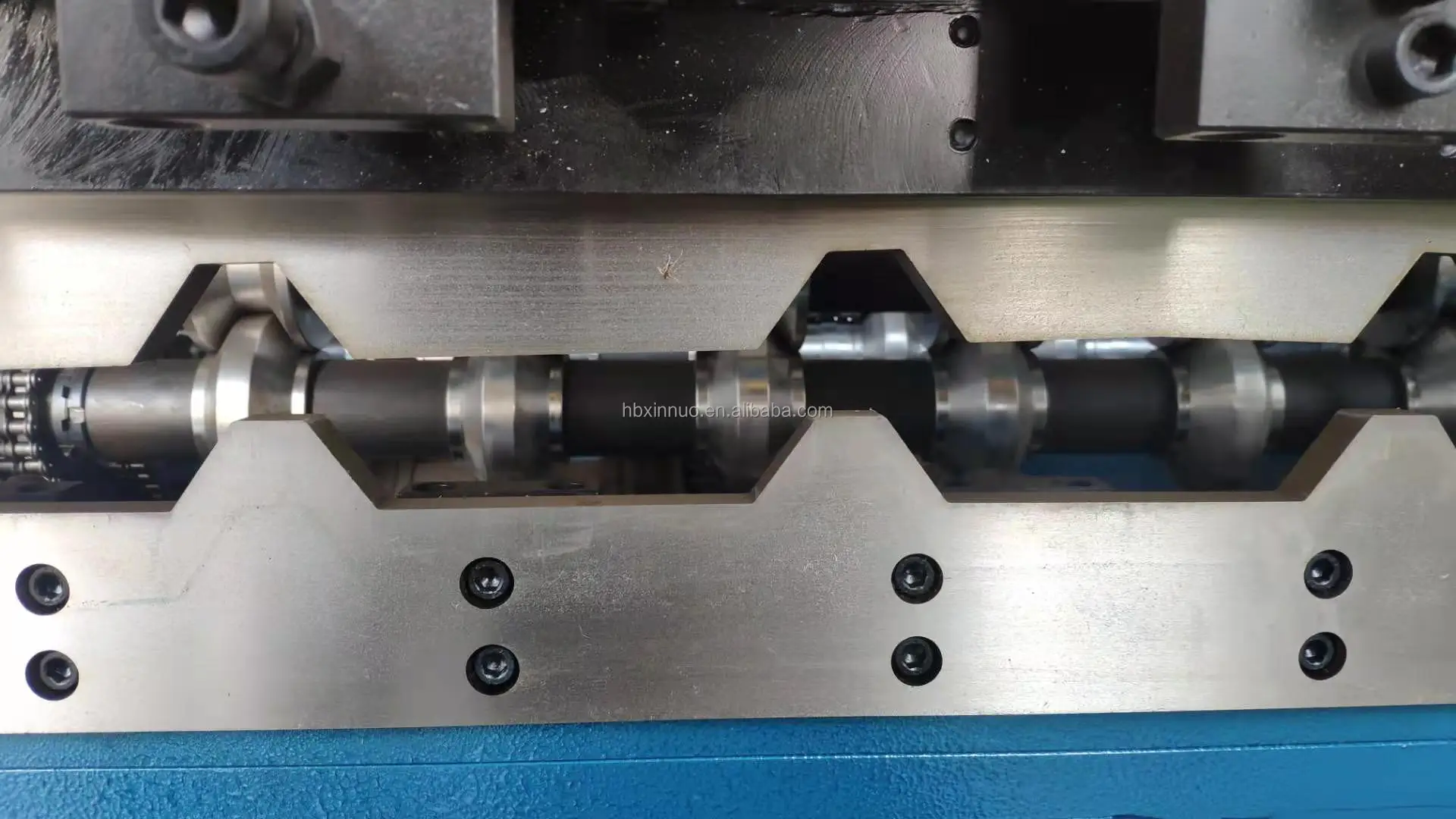

Rollers for forming

|

12 rows

|

|

6

|

Diameter of the roller

|

80mm

|

|

7

|

Rolling material

|

Carbon Steel 45#

|

|

8

|

Main motor power

|

4kw

|

|

9

|

Productivity

|

0-3m/min

|

|

10

|

Cutting method

|

Hydraulic and guide pillar cutting

|

|

11

|

Material of the cutting blade

|

Cr12

|

|

12

|

Hydraulic cutting power

|

3kw

|

|

13

|

Processing precision

|

Within 1.00mm

|

|

14

|

Control system

|

Delta PLC control

|

|

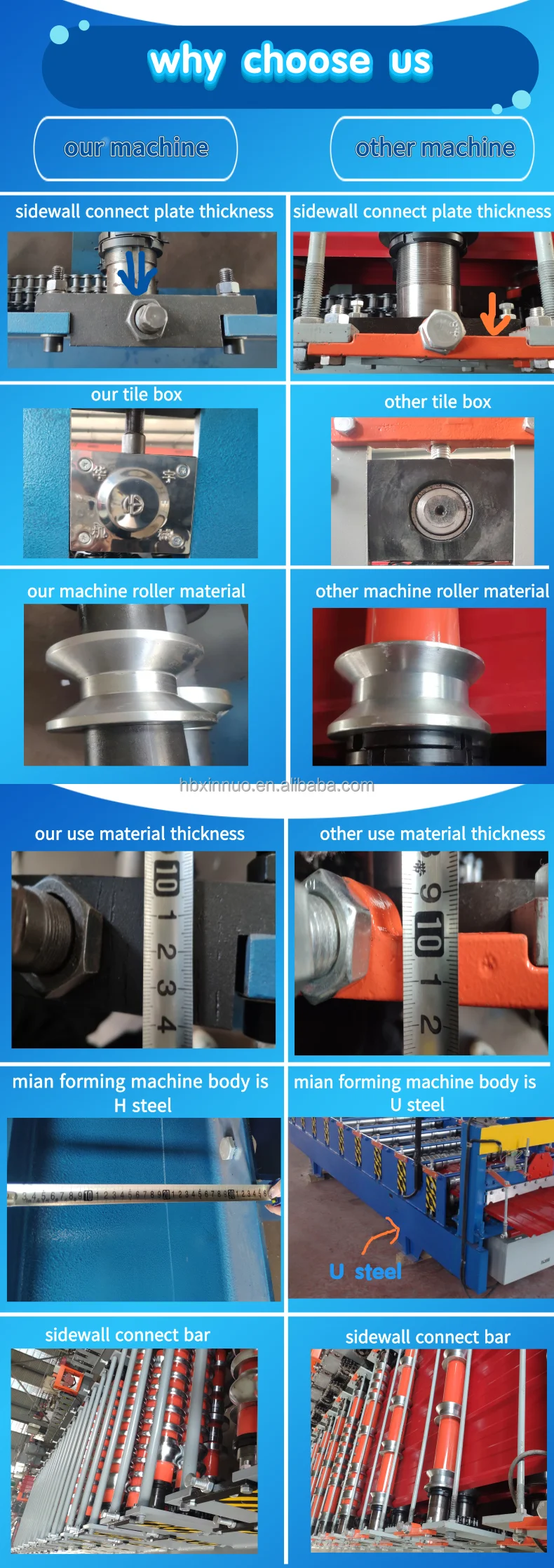

15

|

Side panel of machine

|

14mm

|

|

16

|

Main structure of the machine

|

300 H steel

|

|

17

|

Weight

|

About 4.0T

|

|

18

|

Dimensions

|

7.0*1.5*1.55m

|

|

19

|

Voltage

|

380V 50Hz 3phases(changeable as needs)

|

|

20

|

Certificate

|

CE/ISO

|

|

21

|

Custom

|

According to customer’s requirements

|

|

Packaging Details:

|

Main machine is nude, the computer control box is packed with wooden frame.

|

|

Main machine is nude in the container, the computer control box is packed with wooden packaging.

|

|

|

Delivery Detail:

|

20 days

|

The Xinnuo Master Rib Box Rib PIR PBR Panel Cold Roll Forming Machine represents a significant advancement in the field of roll forming technology. This article serves as a comprehensive guide to understanding the capabilities and benefits of this innovative machine. From exploring its key features and specifications to examining its applications in various industries, readers will gain valuable insights into how the Xinnuo Master Rib Box Rib Machine can revolutionize the production of PIR and PBR panels. Additionally, this article will delve into operating and maintenance procedures, highlight comparisons with traditional forming methods, showcase real-world case studies, and provide a glimpse into the future trends shaping the roll forming industry.

Introduction to Xinnuo Master Rib Box Rib PIR PBR Panel Cold Roll Forming Machine

If you’ve ever wondered how ribbed panels are made, the Xinnuo Master Rib Box Rib PIR PBR Panel Cold Roll Forming Machine is here to save the day. This nifty piece of machinery takes flat metal sheets and magically transforms them into sleek, ribbed panels used in a variety of applications.

Overview of Cold Roll Forming Technology

Cold roll forming is the process of shaping metal sheets at room temperature using a series of rollers. This method allows for precise and consistent shaping of metal, making it ideal for creating complex profiles like those found in rib panels.

Evolution of Roll Forming Machines

Roll forming machines have come a long way from their humble beginnings. Gone are the days of manual shaping – modern machines like the Xinnuo Master Rib Box Rib Machine are efficient, precise, and capable of producing high-quality panels at lightning speed.

Key Features and Specifications of the Xinnuo Master Rib Box Rib Machine

Design and Construction

The Xinnuo Master Rib Box Rib Machine boasts a sturdy construction and a smart design that ensures seamless operation. Its ergonomic layout makes it easy to use, while its robust build guarantees durability even under heavy usage.

Technical Specifications

Equipped with cutting-edge technology, this machine can handle various metal sheet thicknesses and produce panels of different dimensions. With customizable settings and precise controls, it’s a versatile tool for creating rib panels to fit any project.

Applications and Benefits of Using PIR and PBR Panels

Industrial and Commercial Applications

PIR and PBR panels are versatile building materials widely used in industrial and commercial construction. From warehouses to factories, these panels offer superior insulation, durability, and aesthetics, making them a top choice for many projects.

Advantages of PIR and PBR Panels

The use of PIR and PBR panels brings a myriad of benefits, including energy efficiency, cost-effectiveness, and reduced construction time. These panels not only enhance the aesthetics of a building but also improve its overall performance and sustainability.

Operating and Maintenance Procedures for the Roll Forming Machine

Startup and Shutdown Procedures

To ensure smooth operation, proper startup and shutdown procedures are crucial. From initializing the machine to shutting it down safely, following the guidelines provided by the manufacturer is key to preventing mishaps and maximizing efficiency.

Maintenance Schedule and Best Practices

Regular maintenance is essential for keeping your roll forming machine in top condition. From lubricating moving parts to inspecting for wear and tear, adhering to a maintenance schedule and adopting best practices will extend the lifespan of the machine and ensure consistent performance.

Comparison with Traditional Forming Methods

Efficiency and Precision

Forget about the days of clunky, time-consuming manual forming methods. With Xinnuo Master Rib Box Rib Machine, you’ll be zipping through your projects with the precision of a ninja and the efficiency of a cheetah on Red Bull.

Cost-effectiveness and Material Waste Reduction

Save your pennies and the planet at the same time! This machine not only keeps your budget happy but also cuts down on material waste like a vegan at a buffet.

Case Studies and Success Stories

Real-world Applications of Xinnuo Master Rib Box Rib Machine

See how real businesses are using the Xinnuo Master Rib Box Rib Machine to transform their operations. From skyscrapers to storage units, this machine is everywhere like a Kardashian on social media.

Customer Testimonials and Feedback

Don’t just take our word for it—listen to the folks who have actually used this machine. Spoiler alert: they love it more than a puppy loves belly rubs.

Future Trends and Innovations in Roll Forming Technology

Advancements in Roll Forming Machinery

The future is here, folks! Discover the latest and greatest in roll forming machinery that will have you saying goodbye to outdated techniques faster than you can binge-watch a season of your favorite show.

Integration of Automation and Industry 4.0 Technologies

Say hello to the future of manufacturing with the integration of automation and Industry 4.0 technologies. This isn’t your grandpa’s manufacturing—this is like The Jetsons meets Iron Man in a factory.In conclusion, the Xinnuo Master Rib Box Rib PIR PBR Panel Cold Roll Forming Machine stands as a testament to the advancements in modern manufacturing technology. With its efficiency, precision, and versatility, this machine offers a competitive edge to industries seeking superior quality and cost-effective solutions for panel production. As we look towards the future of roll forming technology, the Xinnuo Master Rib Box Rib Machine serves as a beacon of innovation, paving the way for continued progress and evolution in the industry.

Frequently Asked Questions (FAQ)

1. What are the main advantages of using PIR and PBR panels in construction?

2. How does the Xinnuo Master Rib Box Rib Machine compare to traditional roll forming machines in terms of efficiency?

3. Are there specific maintenance requirements for the Xinnuo Master Rib Box Rib Machine?

4. Can the Xinnuo Master Rib Box Rib Machine accommodate custom specifications for panel production?

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

-

Factory Cheap Hot High Quality EPS and Rock Woo...

-

OEM/ODM Factory Roof and Wall Sandwich Panel Pr...

-

Factory Supply Fully Automatic Roll Forming Mac...

-

Factory Directly supply China C/U/L/M/W Drywall...

-

What is CZ Purlin Roll Forming Machine and CZ P...

-

Factory directly China Color Metal Steel Fence ...