-

-

-

High-Quality Liming Roll Forming Machine Manufacturers - standing seam panel roll forming machine – Xinnuo

*Detail Standing seam panel roll forming machine is one of the major machines we are providing. With this roll former, panels are formed from color steel sheets with cold roll forming technique. The formed panels are widely applied in roof, wall, and other building parts. The cutters of the panel roll former are made from Cr12 molybdenumvanadium steel, showing high hardness and great wear resistance. Near 20 years’ rich manufacturing experience is a powerful guarantee of the quality of the X... -

Wholesale Foam Shutter Door Production Line Manufacturers - Xinnuo shutter door machine iron sheet rolling machine rolling shutter machine price – Xinnuo

xinnuo shutter door machine iron sheet rolling machine rolling shutter machine price Product Description Equipment components: Man-made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable. Main parameters 1.Echnical parameters Name fully automatic rate ga... -

China Slitting Line Machine Manufacturers - Hydraulic uncoiler – Xinnuo

*Detail This roll forming machine produces roller shutter door with the roll forming technique in a synchronous forming manner. With computer control system, hydraulic shearing, and auto counting system, the production is conducted fully automatically. The roll forming system contributes to smooth and flat panel surface. Supported by an experienced design team, Xinnuo is competent in offering you efficient customization service. Any customization requirements upon panel’s width, thickness, a... -

-

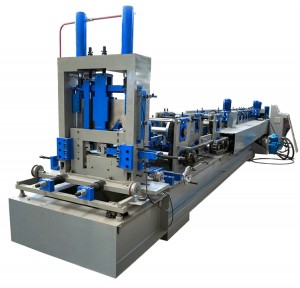

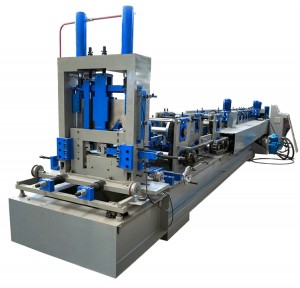

High-Quality Steel Cold Forming Equipment Manufacturers - c purlin roll forming machine – Xinnuo

*Detail C purlin is widely applied in the purlin and wall beams of steel structures. It can be combined into lightweight roof truss, brackets, or other building components, as well as used for columns, beams, and arms in mechanical engineering. Xinnuo has accumulated near 22 years’ experience in producing C purlin roll forming equipment. The C purlin roll former we made is distinguished for competitive price, high stability; and easy operation. It is designed with stepless shearing system, w... -

Wholesale Double Layer Forming Machine Quotes - C Z purlin roll forming machine – Xinnuo

Product Description c purlin roll forming machine use Specification 1. Configation Manual Uncoiler, Guiding Platform, 9 Shaft Strip Leveler, Main Machine Of Roll Forming, Hydraulic Motor, Pre-Punching Device,Pre-Cutting Device, Hydraulic Station, PLC Control, Supporter Table. 2. Control System PLC Inverter Encoder Touch Screen 3. Main Frame 400mm H-Beam 4.... -

Cold Roll Forming Machine Suppliers - Stone Coated Steel Roof Panel Production Line – Xinnuo

*Detail Xinnuo provides automatic sandblasting line, which is designed to smooth the surface of cold rolled plate. The sandblasting equipment we provide is generally used as a part of panel roll forming line. The panels after sandblasting treatment can be applied as UV-proof/thermal-insulated roof panels. Featuring light weight, high strength, bright color, anti shock, water proof, fire proof, long service life, and maintenance free, the panels produced by our roll former are widely used for... -

-

High-Quality Shutter Door Roll Forming Machine Quotes - C Z purlin roll forming machine – Xinnuo

Product Description c purlin roll forming machine use Specification 1. Configation Manual Uncoiler, Guiding Platform, 9 Shaft Strip Leveler, Main Machine Of Roll Forming, Hydraulic Motor, Pre-Punching Device,Pre-Cutting Device, Hydraulic Station, PLC Control, Supporter Table. 2. Control System PLC Inverter Encoder Touch Screen 3. Main Frame 400mm H-Beam 4.... -

Wholesale Cutting Machine Factories - Hydraulic uncoiler – Xinnuo

*Detail This roll forming machine produces roller shutter door with the roll forming technique in a synchronous forming manner. With computer control system, hydraulic shearing, and auto counting system, the production is conducted fully automatically. The roll forming system contributes to smooth and flat panel surface. Supported by an experienced design team, Xinnuo is competent in offering you efficient customization service. Any customization requirements upon panel’s width, thickness, a... -

-

China Seamless Gutter Machine Suppliers - rain gutter forming machine – Xinnuo

*Detail Rain Gutter equipment is the production of building roof gutter roll forming machine, the production of gutter refers to the building roof between the two hip concave part, used for house drainage. Xinnuo Gutter roll forming machine is designed with a dimension of 8.2 *1.3*1.5m. It is distinguished for stable performance, high price/performance ratio, and easy operation. The gutter roll former in Xinnuo has been certified by CE. ISO, and TUV Xinnuo has been developing and producing c... -

High Quality Steel Door Frame Machine Quotes - shutter door roll forming machine with two patterns. – Xinnuo

*Detail This roll forming machine produces roller shutter door with the roll forming technique in a synchronous forming manner. With computer control system, hydraulic shearing, and auto counting system, the production is conducted fully automatically. The roll forming system contributes to smooth and flat panel surface. Supported by an experienced design team, Xinnuo is competent in offering you efficient customization service. Any customization requirements upon panel’s width, thickness, a... -

-

-

High Quality Roll Forming Machine Price Manufacturers - Highway Guardrail Roll Forming Machine – Xinnuo

*Detail Xinnuo highway guardrail roll forming machine is comprised of roll former unit, press. decoiler, receiving rack, and computer control system. It is designed especially to produce highway guard rail, which works to transfer the impact energy through the deformation of column and beam, to force the out-of-control vehicle to go back to its original direction, and to protect the vehicles and passengers to the max extent. *Working Process: Uncoiler—Levelling and Feeding—Punching—Encoder... -

-

Roll forming equipment supplier

More Than 30+ Years Manufacturing Experience

- info@hbxinnuorollforming.com

- 0086-15632788505