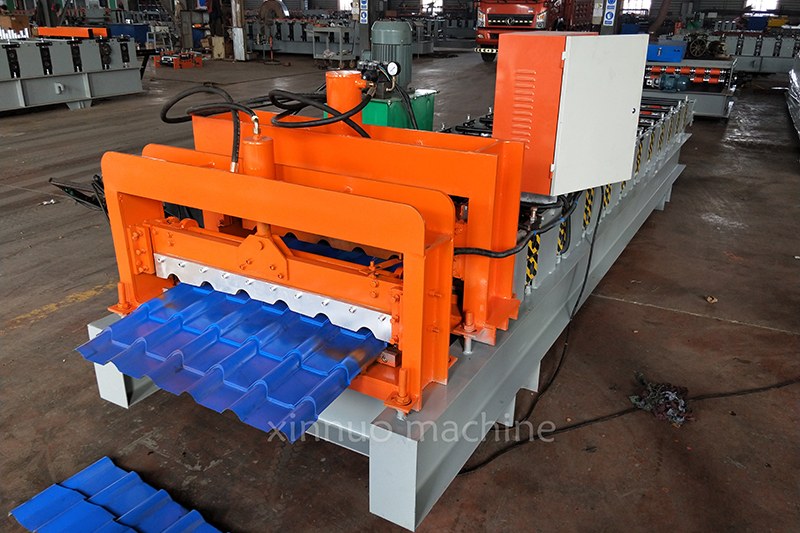

Free sample for Deck Roll Forming Machine - glazed tile roll forming machine – Xinnuo Detail:

*Detail

Metal roof tile roll forming machine for 0.27mm-O.8mm color steel plates or galvanized sheets.

The metal roof tile roll forming machine is made to produce tiles with the appearance of traditional terra cotta and reflect the far-reaching Chinese culture. It is able to process metal roof tiles with various colors from matte to glossy.

The unit weight of metal roof tile the roll former manufactures is only 1/10 of that of terra cotta, but its strength reaches a high level which is unattainable for terra cotta. Metal roof tile is designed with extremely strong resistance to wind and climate. Its service life is as long as 30 years, which is powerfully guaranteed by the multi-coating treatment on the metal glazed tile’s surface. The combination of seamless connection and comprehensive sealing components makes metal roof tile unparalleled in terms of waterproof performance.

This metal roof tile roll former is particularly suitable for light steel structure, concrete structure. wood structure, and some slope structures.

*Features

a. The roof tile roll forming machine adopts synchronous control and is designed with 9-line roll forming technique. The processed panels are given flat and smooth surface.

b. With servo motor and main drive shaft, the plate forming speed of the panel roll former is up to 4-6 m.min, far greater than that of common ones, whose speed is no more than 2m mm.

c. To meet the high efficiency requirements of 4zmin, the roll forming machine is equipped with 7kw motor and large-power oil pump attached ith cooling system.

*Different kinds of metal roof tiles

1. 1100type metal roof tile is the most commonly seen one among partial arc metal tile roofs. It is especially popular in Russia, Uzbekistan, Kazakhstan, Republic of Belarus and so on

2. 828-1035 metal roof tile is a kind of arc roof tile.Among all of the metal roof tiles it is the cheapest one

3. 900/950 series metal roof tile is stepped type.It has found large popularity mainly in Africa.

4. 960 metal roof tile is a kind of corrugated roof tile

*Application

*Sample

Product detail pictures:

Related Product Guide:

carry on to further improve, to guarantee merchandise high-quality in line with market and buyer standard necessities. Our organization has a top quality assurance procedure have already been established for Free sample for Deck Roll Forming Machine - glazed tile roll forming machine – Xinnuo, The product will supply to all over the world, such as: Auckland, Myanmar, Mozambique, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.

-

oem Forming Machine quotes - C Z automatic pur...

-

Wholesale Z Purlin Machine Factory - c purlin ...

-

OEM/ODM Supplier Double Layer Roll Forming Mach...

-

Wholesale Deck Floor Roll Forming Machine Quote...

-

Chinese Professional Roll Forming Machine For S...

-

Oem Roll Forming Machine Video Suppliers - Flo...