CZ Purlin Forming Line Machine: Revolutionizing Construction

CZ Purlin Forming Line Machine: Revolutionizing Construction

In the ever-evolving world of construction, efficiency and precision are paramount. This is where the CZ Purlin Forming Line Machine comes into play, offering innovative solutions that have transformed the way purlins are created for construction projects. With its advanced features, this state-of-the-art machine has taken the industry by storm, ensuring faster production, higher quality, and cost-effectiveness.

Streamlined Production Process

Gone are the days of laborious and time-consuming manual purlin forming. The CZ Purlin Forming Line Machine boasts cutting-edge technology that streamlines the production process from start to finish. By automating various steps, including material feeding, punching, roll forming, cutting, and stacking, this machine eliminates the need for multiple workers and significantly reduces the production timeline. As a result, construction projects can be completed in record time, saving both time and money.

Unparalleled Precision and Quality

Precision is crucial for any construction project, and the CZ Purlin Forming Line Machine ensures every purlin produced is flawless. By leveraging advanced computer numerical control (CNC) technology, this machine operates with utmost accuracy, consistently delivering purlins of the desired dimensions. The computerized control system guarantees precise measurements, eliminating human error and minimizing material wastage. This efficiency not only enhances the quality of the purlins produced but also reduces costs associated with rework or rejection due to inaccuracies.

Versatility and Adaptability

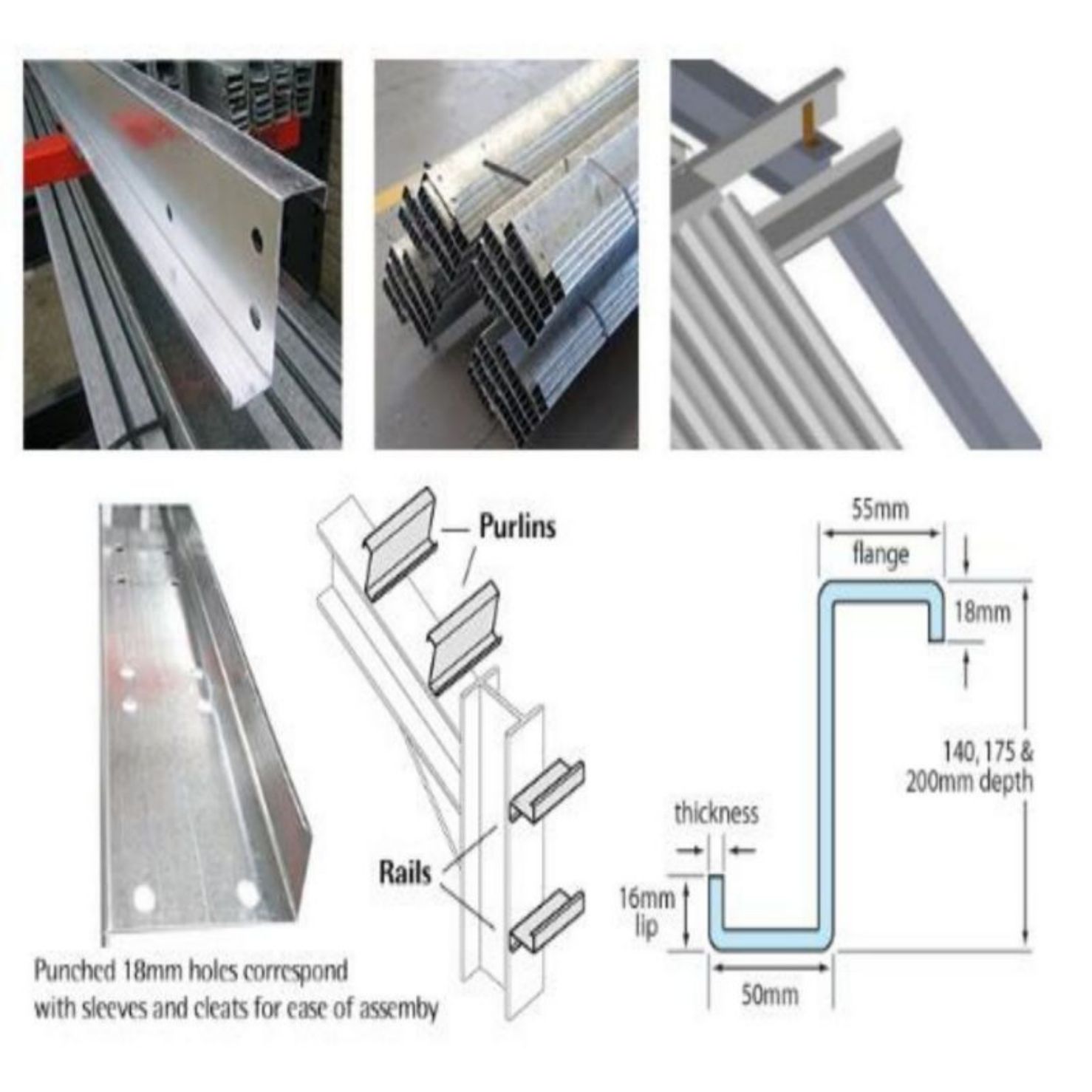

The CZ Purlin Forming Line Machine offers remarkable versatility, making it suitable for various construction projects. It can effortlessly handle different materials, including galvanized steel, cold-rolled steel, and aluminum, adapting to the specific requirements of each project. Moreover, this machine allows for customization, enabling the production of purlins in a wide range of sizes and profiles. With its flexibility and adaptability, construction companies can meet the diverse needs of their clients without investing in multiple machines, providing a competitive edge in the industry.

Efficiency and Cost Savings

Time is money, and the CZ Purlin Forming Line Machine ensures optimal efficiency, translating into significant cost savings for construction companies. With its high production speed and automated processes, the machine reduces labor costs, as fewer workers are needed to operate it. Additionally, the elimination of manual errors and material wastage results in cost savings in the long run. By investing in this cutting-edge technology, construction companies can maximize their productivity while minimizing expenses, contributing to a healthier bottom line.

Enhanced Safety Measures

Safety is of utmost importance in any construction setting, and the CZ Purlin Forming Line Machine takes this aspect seriously. Equipped with advanced safety features, including emergency stop buttons, safety barriers, and sensors, this machine ensures a secure working environment for operators. By complying with international safety standards, it minimizes the risk of accidents and injuries, safeguarding the well-being of workers.

In conclusion, the CZ Purlin Forming Line Machine has revolutionized the construction industry with its efficiency, precision, versatility, and safety measures. By offering streamlined production processes, unparalleled quality, and cost savings, this machine has become an indispensable asset for construction companies worldwide. Embracing this state-of-the-art technology guarantees a competitive advantage, allowing businesses to thrive in today’s fast-paced construction landscape.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.