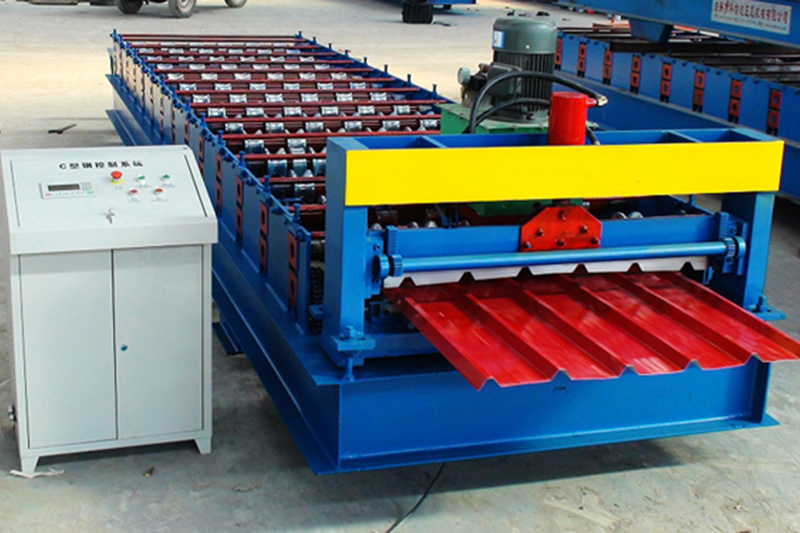

High-Quality Roofing Sheets Machines Factory - roof panel roll forming machine – Xinnuo Detail:

*Detail

Roofing sheet roll forming system is comprised of material feeding, roll forming, and shearing sections. Equipped with PLC computer control system and hydraulic pumping system, the forming machine is of high automation and is easy to be operated.

Xinnuo is able to customize panel roll forming machines used for producing roof panels with different shapes and dimensions according to the standards of different regions. We have 840. 850, and 860 series machines for im-wide panels. For roof panels used in Southeast Asia whose required width is 914mm, we have 760 and 762 series prepared. 1000 series roof panel forming machine is designed for the Middle East where the roof panels are generally 1200mm or 1220mm wide. Customization service is offered by our design team, which is comprised of over 10 professional designers.

This roof panel forming machine is mainly applied in producing roofing panels of plant, warehouse, garage, hangar stadium, exhibition hall, and theaters, etc.

*Features

a. The roof panel roll former is equipped with PLC touch screen control system (multi-language selection system is available upon request)

b. The double-line chain allows for uniform and large transmission force

c. The cutting blades of the roofing sheet roll forming machine is made from Cr12 molybdenum-vanadium steel, featuring high hardness and high wear resistance. The roofing sheet produced by the roll forming machine is distinguished for flat surface

d. Shaft made from 45# steel is designed with a diameter of 80mm

e. 24V constant pressure hydraulic system

f. Shear beam made of 20mm-thick plates

*1000type roll forming machine

| Configurations | Manual Uncoiler ,Guiding Platform ,Coil Strip Leveler ,Main Machine Of Roll Forming ,Electro-Motor,Cutting Device ,Hydraulic Station ,PLC Control, Supporter Table. |

| Control System | PLC Delta Inverter |

| Main Frame | 300mm H-Beam |

| Main Power | 4 kw |

| Pump Power | 3 kw |

| Power Supply | 380V, 3-Phase,50Hz |

| Forming Speed | 15-20m/min |

| Cutting speed | 8-12m/min |

| Roll Station | 14 stands |

| Roller Diameter | 80mm |

| Hydraulic Pressure | 10-12MPa |

| Forming Size | 1000mm |

| Feeding Thickness | 0.3-0.8mm |

| Feeding Width | 1220mm |

| Backboard Thickness | 14mm |

| Chain Size | 20mm |

| Cutter Standard | Cr12 |

| Roller Standard | 45# |

| Cr-Plating Size | 0.05mm |

| Overall Size | 7500×1450×1600mm |

| Total Weight | 4.5T |

All parameters can be customized, we have a high, medium and low version of each machine configuration

*Application

Product detail pictures:

Related Product Guide:

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for High-Quality Roofing Sheets Machines Factory - roof panel roll forming machine – Xinnuo, The product will supply to all over the world, such as: South Africa, Haiti, Eindhoven, Our company has already have pass the ISO standard and we are fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will be the only one can have that products. We hoping that with our good products can bring our customers a great fortune.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.

-

2019 Latest Design Metal Forming Machines - fl...

-

Hot New Products Cold Roll Forming Machines - ...

-

High Quality Roll Forming Machine Manufacturers...

-

Factory Cheap Hot Iron Sheet Making Machine - ...

-

OEM Factory for Liming Roll Forming Machine - ...

-

Metal Roof Forming Machine For Sale - c purlin...