In the dynamic world of construction, metal siding is gaining popularity due to its durability, versatility, and aesthetic appeal. A crucial component in its production is the standing seam roof rolling mill, which plays a pivotal role in creating high-quality metal siding panels. Xinnuo’s standing seam cold roll forming machine has emerged as a leading solution in this field, empowering manufacturers to produce exceptional metal siding efficiently. In this comprehensive article, we will delve into the intricacies of Xinnuo’s machine and explore its various features, benefits, and applications.

Maximizing Efficiency with Xinnuo’s Standing Seam Cold Roll Forming Machine:

Xinnuo’s standing seam cold roll forming machine revolutionizes the production process of metal siding by delivering unparalleled efficiency. Equipped with state-of-the-art technology and advanced design features, this machine ensures seamless operations and consistent quality output. The precision-engineered rollers, combined with Xinnuo’s expertise, allow for precise formation of standing seam profiles, resulting in perfectly shaped metal siding panels.

Unparalleled Versatility, Full Customization:

Designed with versatility and customization in mind, Xinnuo’s standing seam cold roll forming machine caters to a wide range of metal siding requirements. This innovative machine accommodates various metal types, including galvanized steel, aluminum, copper, and stainless steel. It boasts adjustable settings for panel width, height, and rib shapes, allowing manufacturers to produce metal siding panels tailored to specific project needs.

Seamless Integration into Existing Workflow:

Xinnuo understands the importance of seamless integration within the existing manufacturing workflow. The company’s standing seam cold roll forming machine complements this philosophy perfectly. With a user-friendly interface and intuitive controls, operators can easily set up and operate the machine without extensive training. This seamless integration eliminates unnecessary downtime, increasing overall productivity.

Superior Quality Output and Durability:

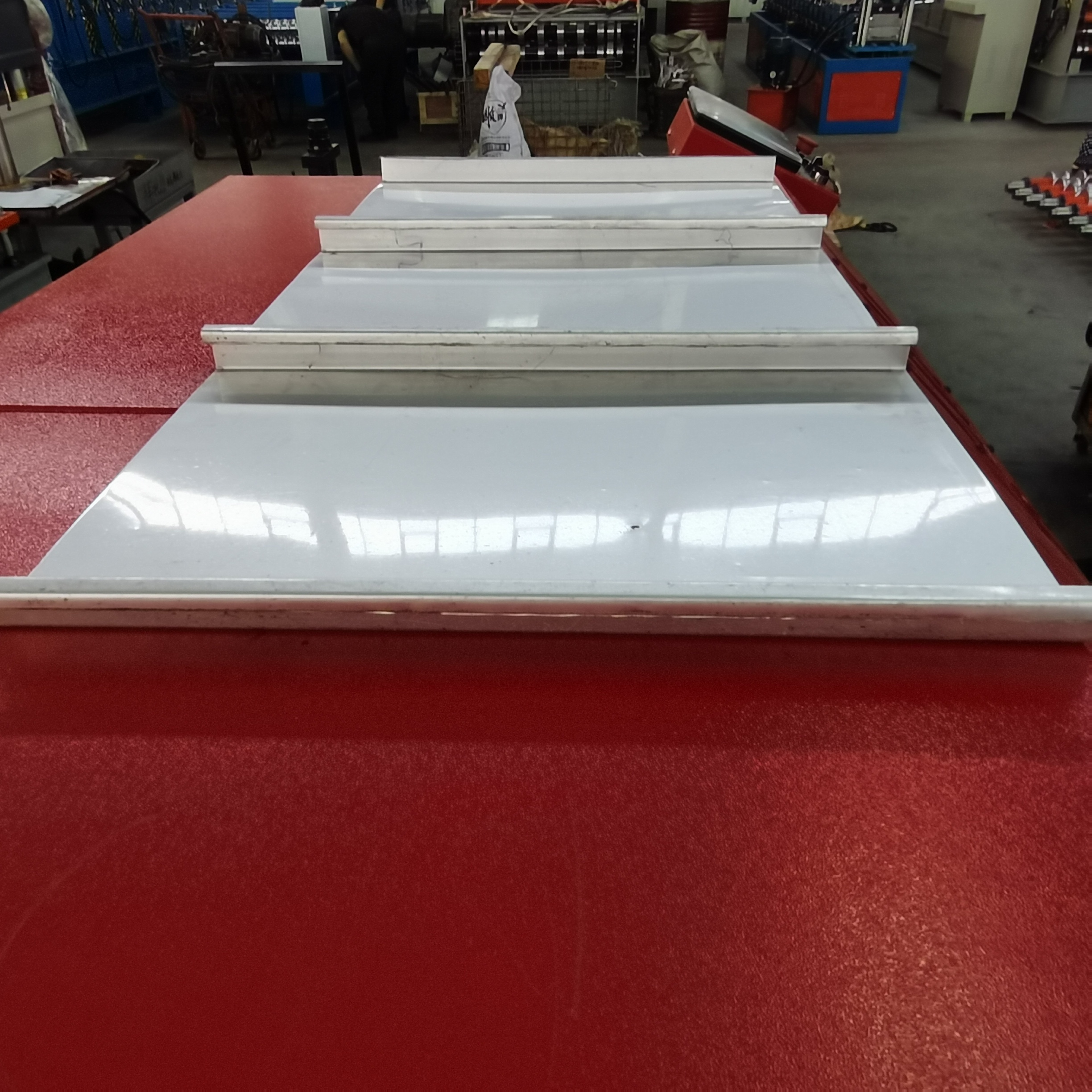

One of the most significant advantages of Xinnuo’s standing seam cold roll forming machine is its ability to consistently deliver high-quality metal siding panels. The machine’s robust construction, precision-engineered components, and cutting-edge technology ensure the utmost accuracy during the forming process. This translates into superior quality output with flawless seams and exceptional panel surface finishes.

Enhancing Efficiency with Advanced Automation:

Xinnuo takes automation to the next level with their standing seam cold roll forming machine. Leveraging sophisticated control systems and advanced sensors, the machine automatically adjusts settings to maintain optimum performance and accuracy. This advanced automation reduces the risk of human error, minimizes material wastage, and optimizes overall production efficiency.

Applications and Benefits for Manufacturers:

With Xinnuo’s standing seam cold roll forming machine, manufacturers can explore a multitude of applications, unleashing their creativity and meeting diverse market demands. Whether it’s for residential homes, commercial buildings, or industrial facilities, this machine caters to wide-ranging project sizes and design specifications. Manufacturers can effortlessly produce metal siding panels with superior aesthetics, excellent weather resistance, and unmatched durability.

Conclusion:

Xinnuo’s standing seam cold roll forming machine is a game-changer in the metal siding industry, offering unrivaled efficiency, versatility, and quality. By incorporating this cutting-edge technology into their production processes, manufacturers can elevate their competitiveness, satisfy customer demands, and achieve remarkable search rankings through the production of exceptional metal siding panels. Don’t miss out on the opportunity to revolutionize metal siding manufacturing – invest in Xinnuo’s standing seam cold roll forming machine today.

Post time: Aug-29-2023