In the world of industrial cable management, the cable tray cold roll forming machine stands as a game-changer. This advanced piece of machinery has revolutionized the production of cable trays, making it easier, more efficient, and cost-effective than ever before. In this informative article, we will delve into the intricate details and functions of the cable tray cold roll forming machine, shedding light on its role in streamlining cable management processes for various industries.

In the world of industrial cable management, the cable tray cold roll forming machine stands as a game-changer. This advanced piece of machinery has revolutionized the production of cable trays, making it easier, more efficient, and cost-effective than ever before. In this informative article, we will delve into the intricate details and functions of the cable tray cold roll forming machine, shedding light on its role in streamlining cable management processes for various industries.

1. Understanding the Cable Tray Cold Roll Forming Machine:

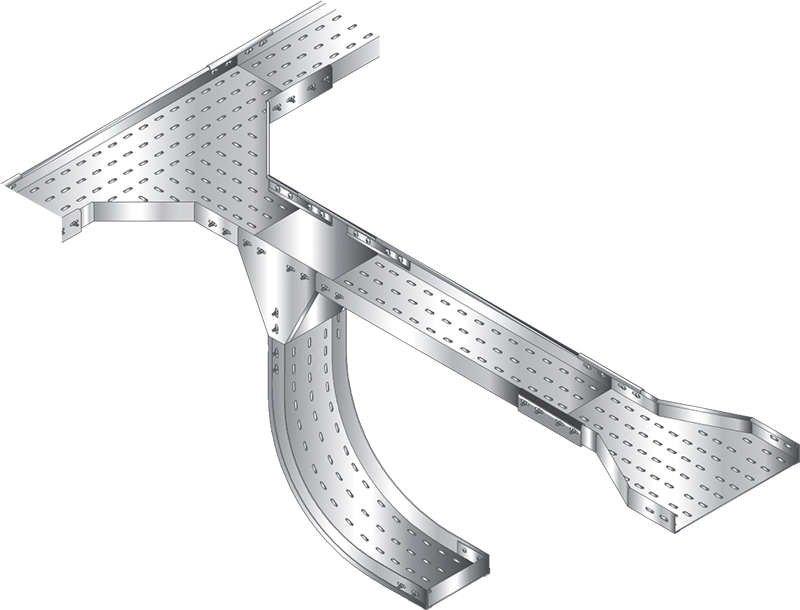

The cable tray cold roll forming machine is a sophisticated piece of equipment designed to produce cable trays of various shapes, sizes, and configurations. Utilizing the cold roll forming process, it takes flat metal coils and transforms them into highly durable and efficient cable management solutions. The resultant cable trays possess exceptional strength, dimensional accuracy, and structural integrity.

2. Unraveling the Cold Roll Forming Process:

The cold roll forming process employed by this machine involves feeding flat metal coil stock into the system. The coil then passes through a series of precisely engineered rollers, which progressively shape the metal into the desired profile. The rollers exert controlled bending and forming actions, ensuring consistent quality throughout the manufacturing process. The cold nature of the process prevents any structural degradation, resulting in superior cable trays with extended service life.

3. Advantages of Cable Tray Cold Roll Forming:

a) Tailored Designs: The cable tray cold roll forming machine empowers manufacturers to create customized cable tray designs with ease. By effortlessly adjusting the machine’s settings, a wide range of profiles and dimensions can be achieved, meeting the unique requirements of diverse cable management applications.

b) Enhanced Efficiency: With high processing speeds, the machine allows for rapid production of cable trays, enabling manufacturers to meet challenging project deadlines and fulfill large-scale orders efficiently. This increased productivity ultimately translates into improved profitability.

c) Cost-effectiveness: The precision and efficiency of the cable tray cold roll forming machine result in minimal material wastage. By using only the required amount of metal, manufacturers can optimize their production costs, making cable trays more affordable without compromising on quality.

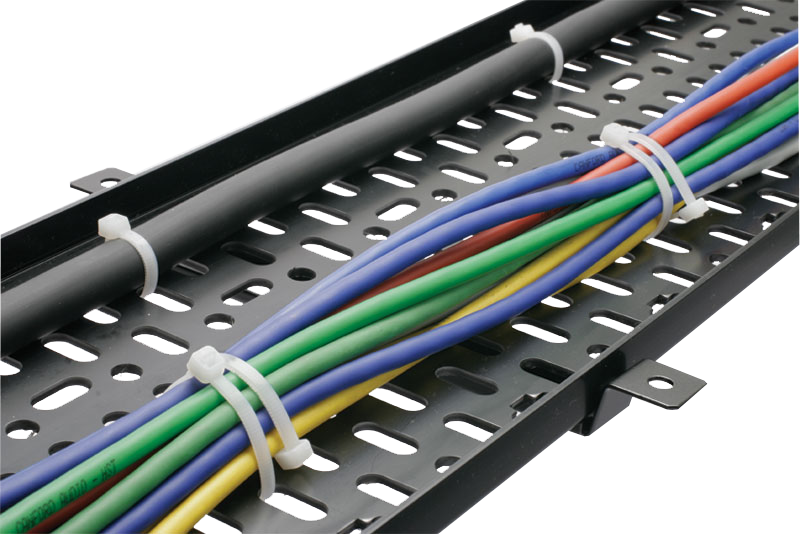

d) Exceptional Durability: Cable trays manufactured using this advanced technology exhibit remarkable strength and longevity. These trays possess high load-bearing capacities, corrosion resistance, and the ability to withstand extreme environmental conditions, ensuring reliable cable management solutions for years to come.

4. Applications and Industries:

The versatility of cable tray cold roll forming machines has expanded their usage across a wide array of industries. From commercial buildings to industrial complexes, infrastructure projects to telecommunications, these machines cater to the cable management needs of diverse sectors. Manufacturing cable trays suitable for power distribution systems, data centers, and cable routing systems, the machine plays a pivotal role in maintaining organized, safe, and efficient cable installations.

Conclusion:

In conclusion, the cable tray cold roll forming machine has become the backbone of modern cable management solutions. By harnessing its precise cold roll forming process, manufacturers can effortlessly produce robust and customized cable trays, meeting the demands of various industries. This advanced machinery offers cost-effectiveness, exceptional durability, and enhanced productivity, ensuring reliable and efficient cable management systems for years to come. Embracing the capabilities of the cable tray cold roll forming machine is a prudent choice for businesses seeking to stay ahead in the ever-evolving world of industrial cable management.

Post time: Oct-09-2023