In this detailed guide, we will explore the manufacturing process of an octagonal tube for a shutter door. The key elements involved in this process include cold roll forming machines, octagonal tubes, octagonal pipes, and the shutter door principal axis. So, let’s delve into the step-by-step procedure of manufacturing this essential component.

In this detailed guide, we will explore the manufacturing process of an octagonal tube for a shutter door. The key elements involved in this process include cold roll forming machines, octagonal tubes, octagonal pipes, and the shutter door principal axis. So, let’s delve into the step-by-step procedure of manufacturing this essential component.

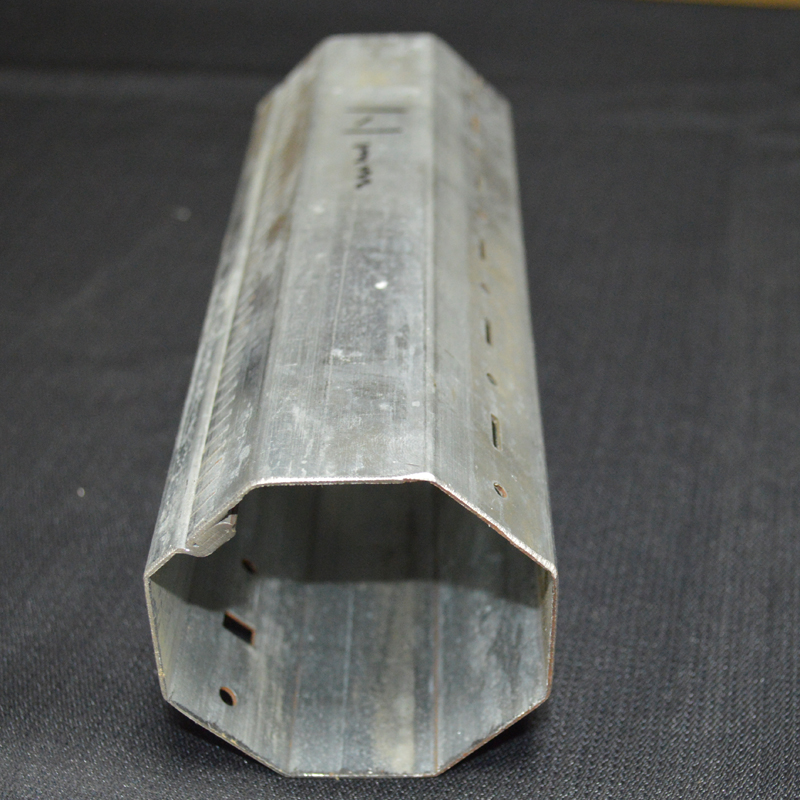

1. Understanding the Octagonal Tube:

Before delving into the manufacturing process, let’s first get acquainted with the octagonal tube itself. An octagonal tube, also known as an octagonal pipe, is a structural component with eight equal sides. Offering increased strength and stability, these tubes are commonly used as the principal axis in shutter doors. Now, let’s move on to the manufacturing process.

2. Choosing the Right Cold Roll Forming Machine:

To begin the manufacturing process, it is crucial to select a suitable cold roll forming machine. This machine will assist in shaping and forming the metal into the desired octagonal tube profile. Ensuring that the machine is capable of handling the required specifications is essential for achieving optimal results.

3. Preparing the Raw Materials:

Next, gather the necessary raw materials, typically steel or aluminum, needed for manufacturing the octagonal tube. Ensure that the materials meet the required strength and dimensional specifications. Clean and inspect the materials for any deformities or imperfections before proceeding.

4. Cold Roll Forming Process:

To form the octagonal tube, the cold roll forming machine undergoes a series of precise operations. The process involves passing the metal strip through rollers, which progressively shape it into the desired octagonal profile. This method ensures a consistent and accurate fabrication of the tube.

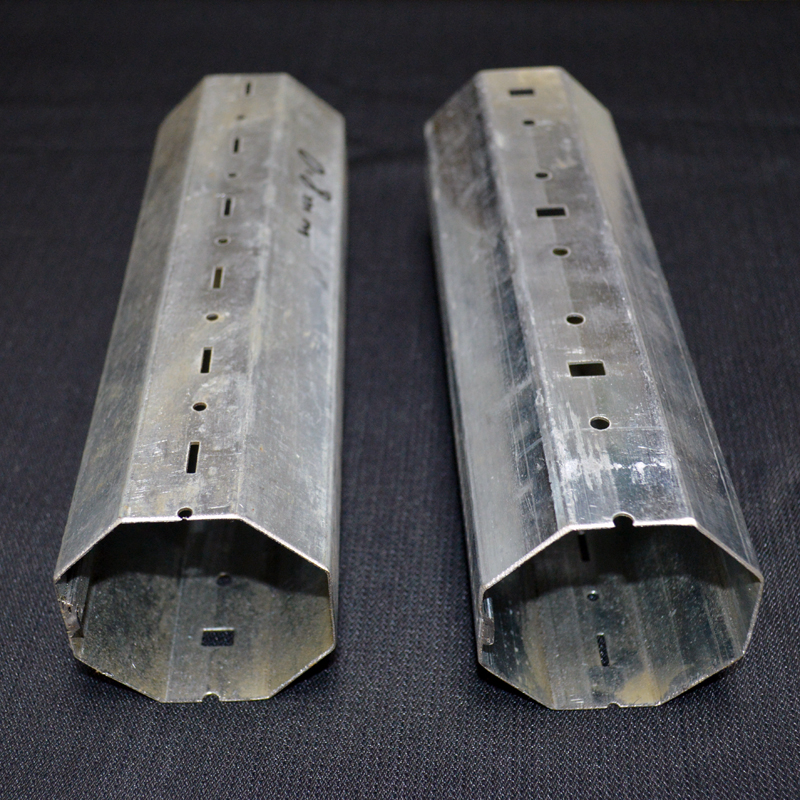

5. Cutting and Finishing:

Once the octagonal tube has been formed, it’s time for cutting and finishing. Utilizing precision cutting tools, the tube is cut to the desired length. Additionally, any burrs or sharp edges are carefully eliminated to ensure a safe and smooth surface for assembly.

6. Quality Control and Inspection:

Before proceeding with the final product, it is crucial to conduct thorough quality control and inspection checks. These tests include assessing the dimensional accuracy, surface finish, and overall structural integrity of the octagonal tubes. This step guarantees that only high-quality components are used in the construction of shutter doors.

Conclusion:

Manufacturing an octagonal tube for a shutter door requires precision, reliable machinery like a cold roll forming machine, and attention to detail. By following the step-by-step process outlined in this guide, you can ensure the production of top-notch components. Remember, quality control and inspection play vital roles in providing sturdy and reliable shutter doors. Implementing these manufacturing procedures will undoubtedly contribute to the success of your octagonal tube production process.

Post time: Sep-18-2023