The world of steel structure manufacturing continues to evolve with the introduction of advanced technology, such as automatic steel structure C/Z purlin rolling machines. These innovative machines have revolutionized the process of forming metal purlins, offering increased efficiency, precision, and cost-effectiveness. In this article, we delve into the realm of automatic steel structure purlin rolling machines, exploring their key features, benefits, applications, and maintenance tips. Join us as we uncover the intricacies of these cutting-edge machines and their impact on the steel construction industry.

1. Introduction to Automatic Steel Structure C/Z Purlin Rolling Machine

Overview of Purlin Rolling Machines

Purlin rolling machines are like the rockstars of the metal fabrication world, cranking out those sleek and sturdy C/Z-shaped purlins that form the backbone of steel structures. These machines are a godsend for anyone looking to whip up purlins with precision and speed.

Significance of Automated Steel Structure Forming

Automated steel structure forming is the futuristic way to go when it comes to churning out those purlins. Say goodbye to manual labor and hello to streamlined processes that save time, effort, and probably a few headaches along the way.

2. Benefits of Using Metal Steel Structure Purlin Rolling Forming Machine

Increased Efficiency and Productivity

With a metal steel structure purlin rolling forming machine in your arsenal, you can kiss goodbye to slow-poke production times. These bad boys are all about cranking out those purlins faster than you can say “steel structure.”

Cost Savings and Material Utilization

Let’s talk dollars and cents, shall we? These machines are not just efficient at what they do; they’re also pretty thrifty when it comes to saving on material waste. Say hello to efficiency and goodbye to squandered resources.

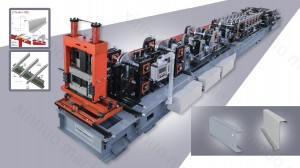

3. Key Features and Components of the Purlin Rolling Machine

Machine Structure and Design

Picture this: a sturdy machine structure that’s as reliable as your grandma’s apple pie recipe. The design of these machines is all about stability and durability, ensuring you can roll those purlins with ease and confidence.

Control Systems and Automation

Who needs manual labor when you’ve got automation at your fingertips? These purlin rolling machines come equipped with control systems that make the whole process a breeze. Sit back, relax, and let the machine do the heavy lifting for you.

4. Understanding the Process of Steel Structure Purlin Rolling

Material Feeding and Forming

It’s all about feeding that material into the machine and watching the magic happen. The material goes in, the machine does its thing, and voila – you’ve got yourself a perfectly formed purlin ready to take on the world.

Rolling and Shaping Techniques

Rolling and shaping like a boss – that’s what these machines are all about. Using top-notch techniques, these machines ensure that your purlins come out looking sharp, sleek, and ready to hold up whatever structure you throw their way.

5. Applications and Industries Utilizing C/Z Purlin Rolling Machines

Construction and Building Sector

C/Z purlin rolling machines are a staple in the construction and building sector for producing structural components like purlins with efficiency and precision. These machines play a crucial role in the creation of sturdy frameworks for various construction projects.

Infrastructure Development Projects

Infrastructure development projects rely on C/Z purlin rolling machines to manufacture durable purlins that provide structural support for bridges, highways, and other essential infrastructure. These machines contribute to the strength and stability of structures in large-scale development endeavors.

6. Factors to Consider When Choosing a Purlin Rolling Machine

Machine Capacity and Production Output

When selecting a purlin rolling machine, it’s vital to consider the machine’s capacity and production output to ensure it meets the requirements of your projects. Understanding the machine’s capabilities in terms of speed and workload capacity is essential for efficient operations.

Quality of Formed Purlins and Customization Options

Evaluate the quality of purlins produced by the machine and the level of customization it offers. Opt for a machine that can deliver precise and consistent results to meet your specific project needs. Customization options allow for versatility in producing purlins tailored to different requirements.

7. Maintenance and Care Tips for Prolonging Machine Lifespan

Regular Inspection and Lubrication

To prolong the lifespan of your purlin rolling machine, prioritize regular inspections and proper lubrication. Routine checks can help identify any issues early on, while adequate lubrication ensures smooth operation and reduces wear and tear on machine components.

Troubleshooting Common Issues

Familiarize yourself with common issues that may arise with your purlin rolling machine and learn how to troubleshoot them effectively. Being equipped to address minor problems promptly can prevent larger issues down the line and keep your machine running smoothly for longer.In conclusion, the automatic steel structure C/Z purlin rolling machine stands as a testament to the advancements in manufacturing technology, providing a reliable and efficient solution for producing high-quality metal purlins. As industries continue to embrace automation and innovation, these machines play a crucial role in streamlining production processes and enhancing overall productivity. By understanding the capabilities and benefits of these machines, manufacturers can make informed decisions to propel their operations forward in the competitive landscape of steel structure fabrication.

FAQs

1. What are the primary differences between manual and automatic steel structure purlin rolling machines?

2. Can the automatic purlin rolling machine handle different types of steel materials and thicknesses?

3. How often should maintenance checks be performed on the purlin rolling machine to ensure optimal performance?

4. Are there specific safety precautions that operators need to follow when working with the automatic steel structure purlin rolling machine?

Post time: Sep-23-2024