Roofing and waterproofing are important aspects of a home, and proper materials and methods must be used to keep the house airtight and weatherproof.

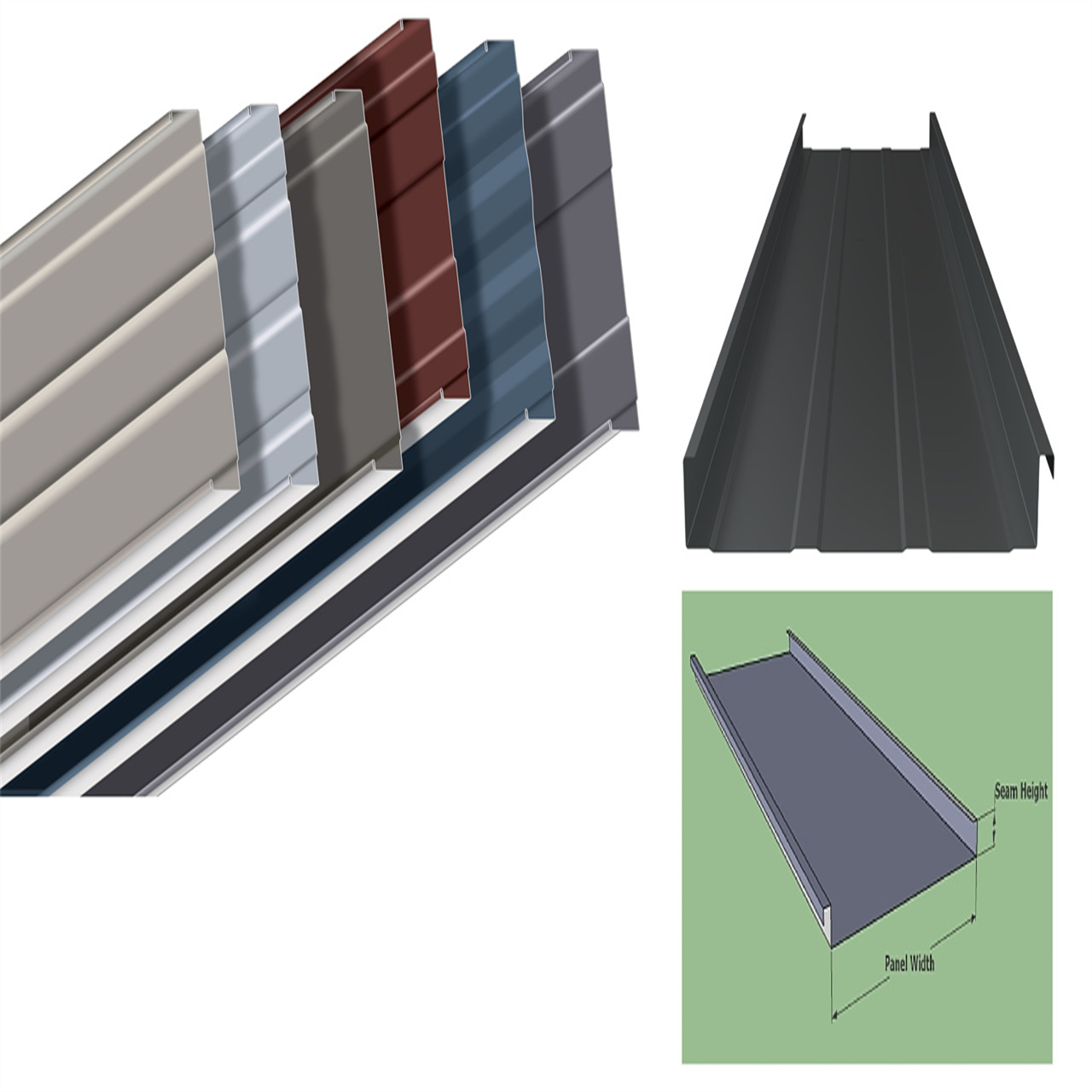

As an alternative to asbestos roofing systems, screw-in metal roofing systems are widely used for industrial and warehouse roofs in India. Trapezoidal roof panels are manufactured according to the project on a modern cold-rolled line of transportable length. The sheets are attached to the roof structure using specially designed self-tapping screws with aluminum washers, and all longitudinal and side seams are sealed with silicone sealant and butyl tape to ensure tightness. In this system, the roof surface is infiltrated, so high quality workmanship and maintenance of the roof are essential for an airtight roof. PK Nagarajan, CEO of Tiger Steel Engineering (India), explained: “As an improvement, we have introduced a standing seam metal roofing system that completely eliminates seepage from the roof surface. along with the necessary raw materials.Because the roof panels are locally produced, they can be one length from ridge to eaves without worrying about transportation restrictions.This eliminates longitudinal seams and avoids the use of traditional sealing materials.Makes the roof less prone to leaks due to sealant wear Another interesting technical feature of this roof system is the concealed clips attached to the steel structure, on which the side plates of the roof panels are rolled and threaded through a 180 electric sewing machine. The galvanized coating is sewn onto the 3600 Double Lock. Floating clips are provided for thermal movement of the shingle, and the double lap seam, together with hidden clips, provides reliable protection against wind uplift and also provides an airtight roofing system. “This is definitely one of the major technological advances for a country like India where most of the country experiences strong monsoons for about 3-4 months of the year. All over the world, asbestos-free corrugated roofing sheets are produced using a moisture-curing technology with a large volume of cement, which ensures a high density and greater sheet weight. “HIL has developed an advanced technology for the production of asbestos-free corrugated roofing sheets, which are autoclaved and require less cement to produce a lightweight, low-density sheet. have low dry shrinkage and thus are expected to have excellent storage performance and durability,” said Dhirup Roy Chowdhary, Chief Executive Officer and Managing Director of HIL Limited (CK Birla Group).

Material Advantages Traditional asbestos-free roof panels use cement, limestone, microsilica and bentonite as binders as raw materials, and polyvinyl alcohol, polypropylene and wood pulp as reinforcing materials. Roofing materials commonly used in metal roofing can be divided into colored roofing panels and colorless roofing panels. At the top of the scale, both colored and non-aluminum shingles are used for trapezoid shingles as well as standing seam shingles. “Aluminum roof panels are considered superior due to their corrosion resistance, better insulation properties, lighter weight and better resale value at the end of their life. Galvanized metal is a traditional material that has been used for a long time in India. Examples of this can be seen in old industrial buildings such as GI corrugated panels. Previously, the panels had a 120gsm zinc coating performance and corrosion resistance,” Nagarajan added. Special coatings for aluminum and zinc, commonly known as galvalume, have become popular in India as they combine the good corrosion resistance properties of aluminum and zinc, providing users with a viable alternative in terms of cost and performance.Similarly, COLORBOND STEEL is one of the world’s most advanced and reliable pre-painted steels for the construction industry, providing design flexibility and superior aesthetics for general applications. structures, in addition to performance. Some of its variants have been developed specifically for industrial and coastal environments. ZINCALUME steel, the base material for COLORBOND steel, provides superior corrosion resistance up to four times longer than galvanized steel with the same coating thickness. COLORBOND steel is not just painted, but has a paint system that ensures longer life and superior aesthetics. “The unique composition of the coating system consists of stable resins and inorganic pigments that do not degrade even under strong UV light, thus preventing fading and chalking for a longer period. developed in consultation with the world’s leading color consultants and construction experts. One of its technological breakthroughs is THERMATECH technology, which reflects solar heat to help keep rooftops cool, therefore reducing indoor temperatures and overall energy consumption,” says Mahendra Pingle, Deputy General Manager Market. Developed by Tata BlueScope Steel.

The mode in which Xinyuanjing cooperates with developers mainly depends on the nature of the project. “On the one hand, we only provide materials for the project in accordance with the requirements put forward by the developer, and on the other hand, we also design the waterproofing system together with the builder and recommend the most suitable waterproofing system according to the requirements of the project. In some cases, we also carry out installation, application and audit of waterproofing systems and provide developers with an end-to-end guarantee,” says Bahadur. Nahul Jagannath, co-founder of Aquaseal Waterproofing Solutions, added: “Each developer has different needs and requirements. We at Aquaseal discussed in detail what the project would require, what the risk appetite of the developer would be, and then we came up with a project that could use alternative methods. “We also understand that there is no one size fits all approach. We are constantly adjusting our initial plans as needed. We have also used several methods on the project in the past, providing end users with a good, durable waterproof design.” Adds Rajeev Jain, director of Nirmal: “We use different coatings depending on the project. We use hydromax foundation waterproofing, drainage mat system, valuable insulating waterproofing, self-adhesive sheet membrane, bentonite geotextile system, moisture recovery Epoxy coatings, hybrid polyurethane coatings and crystal water protection These waterproofing materials are divided in terms of the materials used and the process used.”

Going Green HIL has developed asbestos-free roofing sheets under the brand name Charminar Fortune, which are environmentally friendly because the product does not use hazardous materials, generates no waste, and does not consume by-products of other industries such as flies. ash and cotton waste from thermal power plants used for production. About 80% of this raw material comes from less than 150 km, is 100% recyclable and has no negative impact on society. The main goals of sustainable roofing materials are to reduce or completely prevent the depletion of essential resources such as energy, water and raw materials, prevent environmental degradation and create a livable, comfortable, safe and efficient built environment. “THERMATECH technology reduces heat transfer to the inside of a building, thereby improving thermal performance and cooling comfort. COLORBOND steel reduces roof temperature peaks by up to 60°C on hot days. Depending on the level of insulation, color, building shape, orientation and features, it can also reduce annual cooling energy consumption by up to 15 percent,” added Pingle. Tata BlueScope Steel is committed to creating sustainable and innovative building materials and products that help reduce environmental impact. coated is 46 W/mK, and the thermal insulation performance is expected to be better than color-coated plates.“Due to the relatively light weight of the paper, the shipping cost per sheet is also low. The low weight of cardboard also helps to reduce the overall cost of construction compared to other alternatives. Thus, it turns out to be very beneficial in all aspects. Innovative product Weight It is light, strong and meets the requirements of national and international standards such as IS 14871, EN 494 and ISO 9933,” says Chowdhary.

Product Range Similarly, there are many waterproofing coatings on the market. Pidilite Industries has the largest range of coatings in the waterproofing industry in India from Dr Fixit. “We offer coatings based on cement, acrylic, asphalt, polyurea and other hybrid coatings. These coatings have countless applications depending on the surface they are applied to. Due to the wide range of products in our range, it is difficult to comment on how they differ, because one product for a particular surface is not suitable for another surface,” said Dr. Sanjay Bahadur, Global General Manager, Construction Chemicals, Pidilite Industries.The uniqueness of a product is based on several parameters such as expected performance, service life, elongation, and also the overall durability and maintenance of the product.Aquaseal Waterproofing uses a variety of waterproofing coating systems such as acrylic, crystal, polyurethane systems.Each of these coating systems has its own unique characteristics.There are two types of acrylic coating systems: two-component acrylic systems coatings (2K) and crystal coating systems. “Two-component acrylic paint systems (2K) are paint systems mixed with polymer modified powders and are mainly used for waterproofing wet areas such as bathrooms, utilities, etc. These paints are elastic in nature, but not may be exposed to sunlight. On the other hand, one-component acrylic paint (1K) has more or less the same flexibility and strength, but can be exposed to sunlight,” says Manish Bhavnani, owner of Aqua Seal Waterproofing Solutions. Crystalline coating systems are active systems, i.e. their property to form insoluble crystals in the structure of concrete is maintained throughout the entire service life of concrete. The system acts as a catalyst in concrete elements to initiate crystal growth, stopping water intrusion the moment the structure is exposed to water. The system becomes stronger with water, ideal for handling difficult spills. Polyurethane-based coating systems are very flexible and durable with an elongation of approximately 250-1000%. These systems are ideal for large areas such as patios, podiums and more. They form a seamless coating without any seams. Innovations in the field of waterproofing are also appearing on the market. Last year, Pidilite launched two revolutionary products from the Raincoat Select and Raincoat Waterproof Coat range, specifically designed for waterproof outdoor applications. “Specially for the roof, we presented “Dr. Fixit Raahat” is essentially a waterproofing + insulation solution that can be used in slums and industrial buildings, as it is a technically superior and durable product compared to aluminum panels. These products have serious claims and we are confident in them. There will be indications; from for the benefits associated with them,” Bahadur said.

Post time: Jan-06-2023