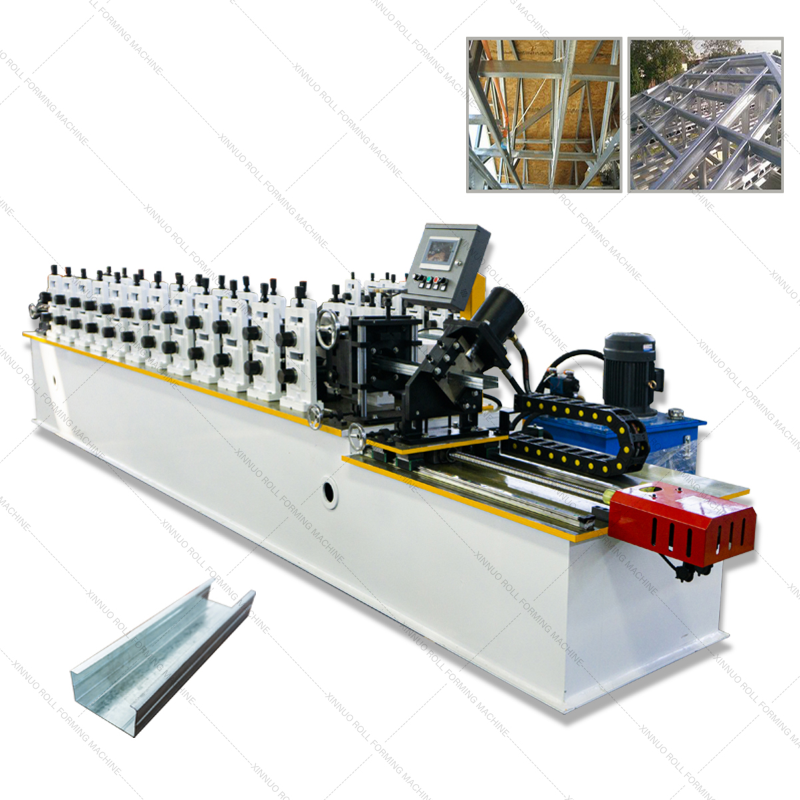

Light keel studs and tracks play a crucial role in modern construction, providing stability, strength, and versatility to various structures. When it comes to manufacturing these essential components, the XINNUO light keel studs and track cold roll forming machine emerges as a top-notch solution. In this article, we delve into the intricacies of light keel studs and tracks, exploring the benefits of utilizing the advanced XINNUO cold roll forming machine to achieve superior results.

Why Light Keel Studs and Tracks Matter in Construction:

1. Durability and Structural Integrity:

Light keel studs and tracks are made from high-quality materials, such as galvanized steel, ensuring exceptional durability and resistance against corrosion. These components serve as load-bearing elements, providing structural stability to walls, partitions, ceilings, and other architectural features.

2. Versatility and Flexibility:

One of the notable advantages of light keel studs and tracks is their flexibility in design and installation. These components can be easily adapted to suit various construction requirements, making them ideal for both residential and commercial projects. With the ability to create customized shapes and sizes, designers can achieve innovative and efficient structures.

3. Acoustic and Fire Resistance:

Light keel studs and tracks can significantly enhance a building’s acoustics and fire resistance. When combined with appropriate insulation materials, these components help control sound transmission between rooms and contribute to a quieter and more comfortable interior environment. Moreover, their non-combustible nature adds an extra layer of safety by preventing rapid fire spread.

The XINNUO Light Keel Studs and Track Cold Roll Forming Machine Advantage:

The XINNUO light keel studs and track cold roll forming machine offers unmatched precision, efficiency, and productivity, revolutionizing the manufacturing process. Here’s why the machine deserves attention:

1. Unwavering Precision:

The XINNUO machine utilizes advanced technology and precise calibration, ensuring each light keel stud and track is fabricated with unparalleled accuracy. This precision guarantees a seamless fit during construction, minimizing wastage and improving overall project quality.

2. Efficient Production:

With the XINNUO cold roll forming machine, manufacturers can achieve high production rates without compromising quality. The automated process eliminates manual labor and reduces manufacturing time, allowing for cost-effective and timely project completion.

3. Versatility in Design:

XINNUO’s machine offers versatile options for generating customized light keel stud and track designs. From adjustable sizes to various thicknesses, the machine adapts to the specific requirements of different construction projects seamlessly. By providing design flexibility, XINNUO empowers builders and architects to bring their unique visions to life.

Conclusion:

In the realm of construction, choosing the right materials and manufacturing methods is crucial to ensure the longevity, strength, and efficiency of structures. Light keel studs and tracks, coupled with the advanced XINNUO light keel studs and track cold roll forming machine, offer unparalleled benefits. Their durability, flexibility, and enhanced properties contribute to safer, sounder, and more aesthetically pleasing buildings. Embracing the XINNUO machine’s precision and efficiency leads to improved construction outcomes, elevating projects to new levels of excellence in the industry.

Note: The content above focusses on highlighting the benefits of light keel studs and tracks and their integration with the XINNUO light keel studs and track cold roll forming machine. It avoids generic filler phrases, self-references, and touches upon important SEO principles, such as using subheadings with keyword-rich titles.

Post time: Sep-15-2023