If you are looking for any machine that works on reels, then you definitely need a decoiler or decoiler.

Investing in capital equipment is an undertaking that requires consideration of many factors and characteristics. Do you need a machine that meets your current production needs, or do you want to invest in next generation capabilities? These questions are often asked by shop owners when buying a roll forming machine. However, research on unwinders has received little attention.

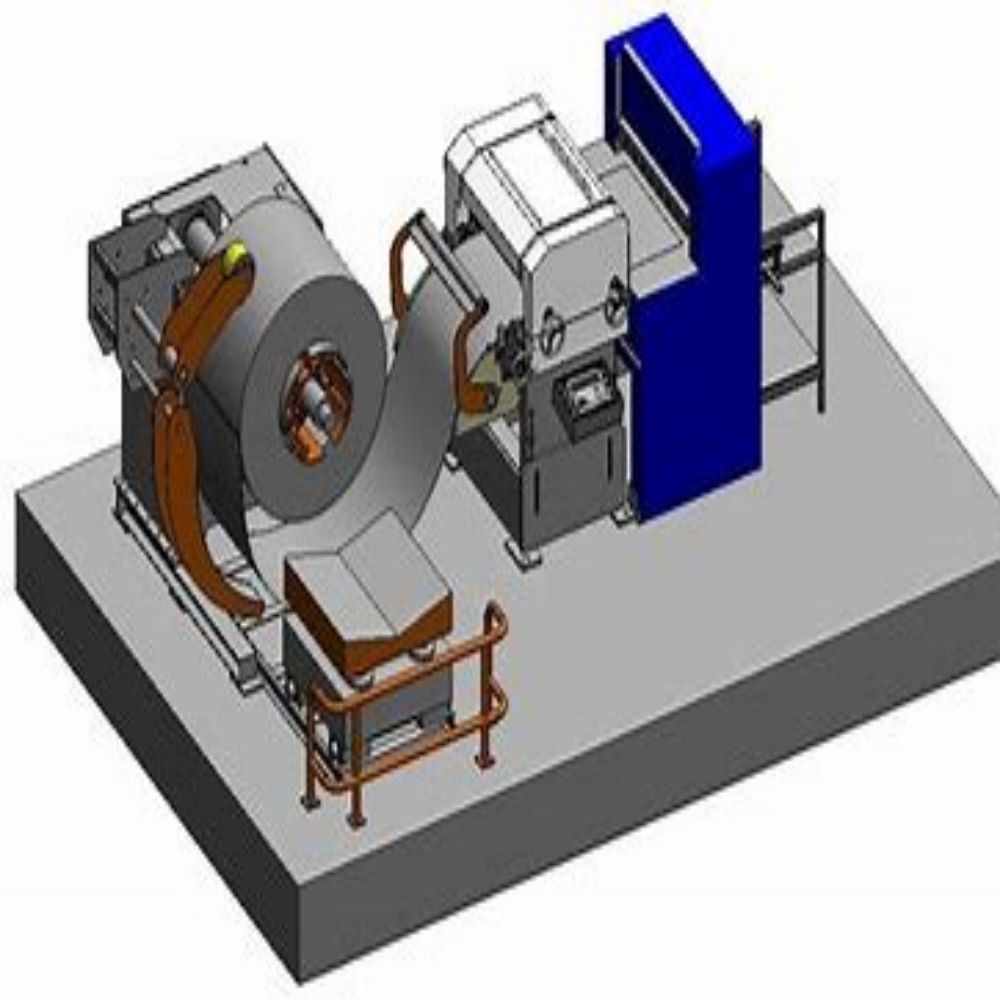

If you are looking for a machine that runs on reels, you will undoubtedly need a decoiler (or decoiler as it is sometimes called). If you have a forming, punching or slitting line, you need a roll unwinder for the following process; there really is no other way to do it. Ensuring that your decoiler fits the needs of your shop and project is critical to keeping your rolling mill in shape, because without material, the machine cannot run.

The industry has changed a lot in the last 30 years, but decoilers have always been designed to meet the specifications of the roll industry. Thirty years ago, the standard outside diameter (OD) of steel coil was 48 inches. As the machines became more individual and the projects called for different options, the coils were adjusted to 60″ and then to 72″. Manufacturers today sometimes use outside diameters (OD) above 84 inches. exist. coil. Therefore, the unwinder must be adjusted to accommodate the changing outside diameter of the roll.

Decoilers are widely used in the profiling industry. Today’s roll forming machines have more features and capabilities than their predecessors. For example, 30 years ago roll forming machines were running at 50 feet per minute (FPM). Now they run at speeds up to 500 FPM. This change in the production of roll forming equipment also increases the productivity and basic set of options for the decoiler. It is not enough to simply choose any standard decoiler, you must also choose the right one. There are many factors and features to consider in order to meet the needs of your store.

Decoiler manufacturers offer many options to optimize the profiling process. Today’s decoilers start at 1,000 pounds. Over 60,000 pounds. When choosing a decoiler, consider the following characteristics:

You also need to consider what type of project you will be doing and the materials you will be working with.

It all depends on what parts you intend to use on your rolling mill, including whether the coils are pre-painted, galvanized or stainless steel. All these characteristics determine which unwinder features you need.

For example, standard decoilers are single-sided, but having a double-sided decoiler can reduce wait times when handling materials. With two mandrels, the operator can load a second roll into the machine, ready to be processed when needed. This is especially useful in situations where the operator needs to change spools frequently.

Manufacturers often don’t realize just how useful an unwinder can be until they realize that, depending on the size of the roll, they can make six to eight or more changeovers per day. As long as the second roll is ready and waiting on the machine, there is no need to use a forklift or crane to load the roll after the first roll is used up. Uncoilers play a key role in a flow forming environment, especially in high volume operations where machines can form parts in an eight hour shift.

When investing in a decoiler, it is important to understand your current performance and capabilities. However, it is also important to consider the future use of the machine and possible future projects on the roll forming machine. All of these factors should be considered appropriately and can really help in choosing the right unwinder.

The bale trolley makes it easy to load the bale onto the mandrel without waiting for a crane or forklift to do it.

Choosing a larger mandrel means you can run smaller rolls on the machine. So, if you choose 24 inches. Arbor, you can run something smaller. If you want to upgrade to 36 inches. option, then you need to invest in a larger decoiler. It is important to look for future opportunities.

As rolls got bigger and heavier, shop floor safety became a major concern. Uncoilers have large, fast-moving parts, so operators need to be trained in the operation of the machine and its correct settings.

Today, roll weights vary from 33 to 250 kg per square inch, and unwinders have been modified to meet roll yield strength requirements. Heavier spools pose more safety concerns, especially when cutting tape. The machine is equipped with pressure arms and buffer rollers to ensure that the rolls are unwound only when needed. The machine can also include feed drives and sideshift bases to help center the bale for the next process.

Expanding the mandrel by hand becomes more difficult as the spool becomes heavier. As shops move operators off the uncoiler to other areas of the shop for safety reasons, hydraulic expansion mandrels and slewing capabilities are often required. Shock absorbers can be added to minimize over-rotation of the unwinder.

Depending on the process and speed, additional security features may be required. These features include outward-facing roll holders to prevent rolls from falling out, roll outside diameter and rotation speed control systems, and unique braking systems such as water-cooled brakes for production lines operating at high speeds. This is very important to ensure that the unwinder stops when the flow formation process stops.

If you are working with multi-color materials, there are special five-mandrel unwinders, which means you can use five different rolls on the machine at the same time. Operators can produce hundreds of parts of one color and then switch to another color without wasting time unloading rolls and switching.

Another feature is the roll trolley, which facilitates the loading of rolls onto mandrels. This ensures that the operator does not have to wait for a crane or forklift to load.

It is important to take the time to explore the various options available for your unwinder. With adjustable arbors to accommodate different inner diameter spools and multiple spool backplate sizes, there are many factors to consider in order to find the right fit. A list of current and potential specifications will help you identify the features you need.

Like any other machine, a roll forming machine is only profitable when it is running. Selecting the right decoiler for your shop’s current and future needs will help your decoiler run more efficiently and safely.

Jaswinder Bhatti is Vice President of Application Development at Samco Machinery, 351 Passmore Ave., Toronto, Ontario. M1B 3H8, 416-285-0619, www.samco-machinery.com.

Stay up to date with the latest news, events and technologies in all metals with our monthly newsletter written especially for Canadian manufacturers!

Full access to Metalworking Canada Digital Edition is now available for quick access to valuable industry resources.

Full digital access to Fabricating and Welding Canada is now available, providing easy access to valuable industry resources.

Available in 15kW, 10kW, 7kW and 4kW, NEO is the next generation of laser cutting machines. NEO is equipped with beam control technology, large front and side inspection doors, and adaptable CNC control for ease of operation.

Post time: Aug-14-2023