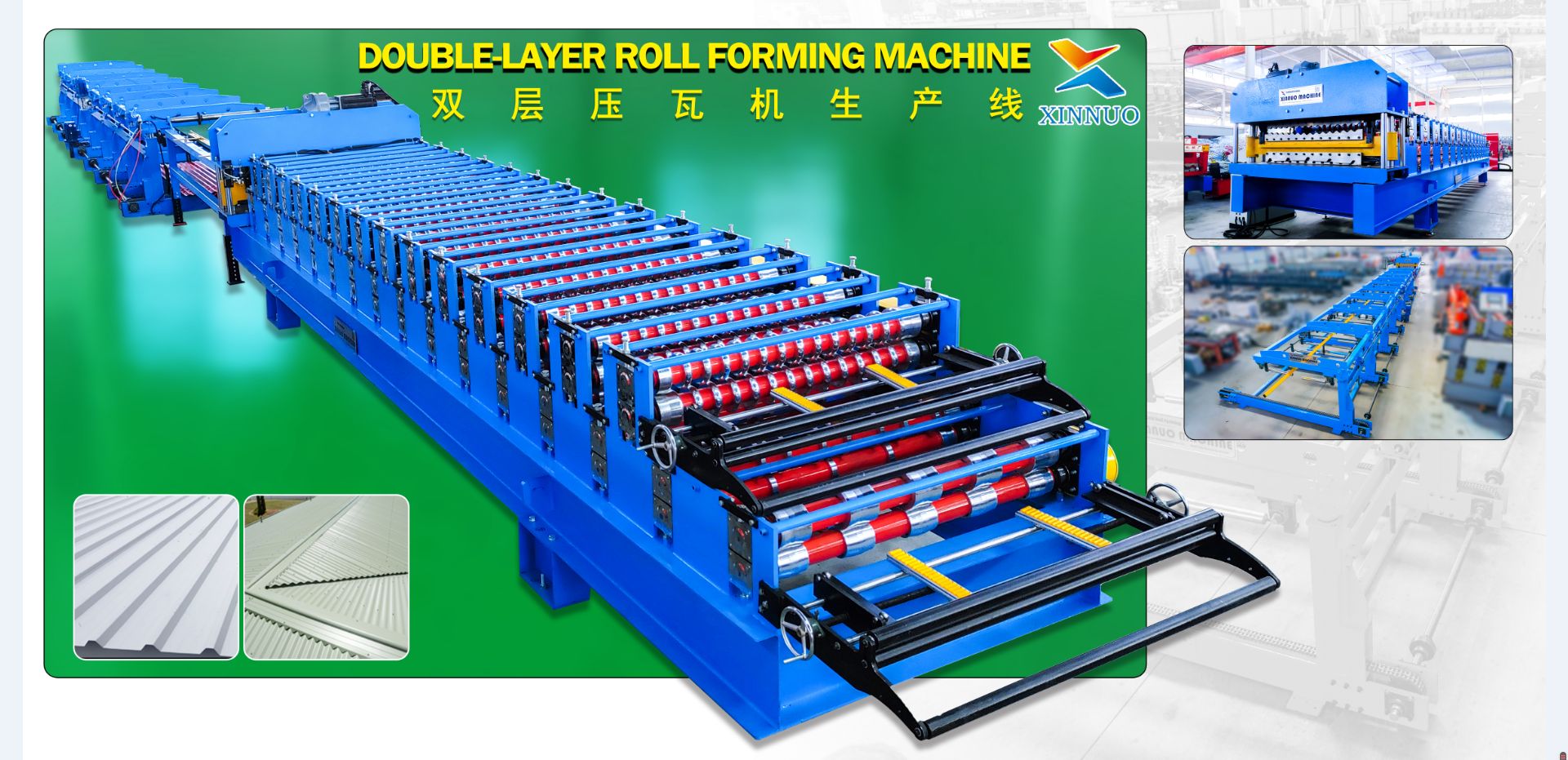

Introducing our innovative Roof Panel Cold Roll Forming Machine, a state-of-the-art equipment designed to revolutionize the roofing industry. With its cutting-edge technology and superior performance, this machine sets new standards in precision, efficiency, and versatility.

The Roof Panel Cold Roll Forming Machine is meticulously engineered using high-quality materials to ensure durability, reliability, and longevity. It features a robust frame that provides stability during operation, even under heavy loads. The machine’s compact design optimizes space utilization, making it suitable for both small and large-scale production environments.

One of the key highlights of this machine is its exceptional cold roll forming capabilities. Cold roll forming is a process that involves shaping and bending metal sheets at room temperature to create complex and accurate profiles. This process ensures excellent precision and consistency, resulting in high-quality roof panels that meet the most rigorous industry standards.

For added flexibility, the Roof Panel Cold Roll Forming Machine is equipped with a user-friendly control system. The operator can easily adjust various parameters, such as machine speed, roll gap, and cutting length, to accommodate different production requirements. The control system also enables seamless integration with other production line components, such as decoilers and stackers, to streamline the manufacturing process.

Moreover, this machine offers an extensive range of profile options, allowing manufacturers to produce a wide variety of roof panels. Whether it’s standing seam roof panels, metal tiles, or corrugated panels, this machine can efficiently and accurately produce them all. The versatility of the Roof Panel Cold Roll Forming Machine makes it an ideal investment for roof panel manufacturers looking to expand their product offerings.

Our Roof Panel Cold Roll Forming Machine is designed to optimize efficiency and productivity. With its high-speed operation, it can produce roof panels at an impressive rate, significantly reducing production time and costs. The machine’s precise forming and cutting mechanisms ensure minimal material waste, maximizing the overall yield. Additionally, its low maintenance requirements minimize downtime, contributing to uninterrupted production.

The safety features of the Roof Panel Cold Roll Forming Machine further enhance its appeal. It is equipped with safety guards and sensors to prevent accidents and protect operators from potential hazards. The machine’s advanced control system also provides real-time monitoring and diagnostics, allowing operators to quickly identify and address any issues that may arise.

In summary, our Roof Panel Cold Roll Forming Machine is a cutting-edge solution that revolutionizes roof panel manufacturing. It combines superior performance, versatility, and efficiency to meet the demanding needs of the industry. By investing in this state-of-the-art machine, manufacturers can enhance their production capabilities, expand their product offerings, and stay ahead in a rapidly evolving market.

Post time: Jul-17-2023