Anish Kapoor’s vision of the Cloud Gate sculpture in Chicago’s Millennium Park resembles liquid mercury, organically reflecting the surrounding city. Achieving this wholeness is a labor of love.

“What I wanted to do with Millennium Park was to do something that mimics the Chicago skyline… so people can see the clouds drift and these very tall buildings are reflected in the work. And then, because it’s at the gate. The form, the participant, the spectator will be able to enter this very deep room, which in some way does to the reflection of a person what the appearance of the work does to the reflection of the surrounding city. Anish Kapoor, Cloud Gate sculptor

Just from the serene surface of the gigantic stainless steel sculpture, it would be hard to guess just how much metal and guts lurk beneath the surface. Cloud Gate contains the stories of over 100 metal fabricators, cutters, welders, finishers, engineers, technicians, fitters, installers and managers – over five years in the making.

Many worked long hours, worked in workshops in the middle of the night, camped on construction sites and worked in 110-degree heat wearing full Tyvek® hazmat suits and half mask respirators. Some work in anti-gravity positions, with tools suspended from harnesses, and work on slippery slopes. Everything goes a little (and far beyond) to make the impossible possible.

Weighing 110 tons, 66 feet long and 33 feet tall, the stainless steel sculpture, which embodies sculptor Anish Kapoor’s ethereal concept of soaring clouds, is the work of Performance Structures Inc., a manufacturing firm. (PSI), Oakland, California, and MTH. Mission, Villa Park, Illinois. At its 120th anniversary, MTH is one of the oldest structural steel and glass contractors in the Chicago area.

Realizing the requirements of the project will require the artistic performance, ingenuity, mechanical knowledge and manufacturing know-how of both companies. They made to order and even created equipment for the project.

Some of the project’s problems were related to its strangely curved shape – an umbilical cord or an inverted navel – and some to its huge size. The sculpture, built by two different companies in different locations thousands of miles apart, created traffic and style problems. Many processes that need to be done in the field are difficult to do on the shop floor, let alone in the field. Many difficulties arise simply because such structures have never been created before, so there are no references, no drawings, no roadmaps.

Ethan Silva of PSI has extensive experience in framing, first for ships and later for other art projects, and is uniquely qualified for the task of framing. Anish Kapoor asked a Physics and Art graduate to provide a small model.

“So I made a 2m by 3m piece, a really smooth curved, polished piece, and he said, ‘Oh, you did it, you’re the only one who did it,’ because he was looking for two years. Come, ask someone to do it,” said Silva.

The original plan was for PSI to fabricate and build the sculpture in its entirety and then ship it in its entirety to the South Pacific Ocean, through the Panama Canal, north into the Atlantic Ocean and via the St. Lawrence Seaway to a port on Lake Michigan, according to the executive director. Edward’s Millennium Park Corporation, a specially designed conveyor system will take him to Millennium Park, Ulliel said. Time constraints and practicality forced changes to these plans. So the curved panels had to be prepared for transport and then trucked to Chicago, where MTH assembled the substructure and superstructure and connected the panels to the superstructure.

Finishing and polishing the Cloud Gate welds to give them a seamless look was one of the most difficult aspects of installation and assembly on site. The 12-step process is completed by the application of a brightening blush, similar to jewelry polish.

“Basically, we worked on this project, making these parts for about three years,” Silva said. “This is a serious undertaking. It takes a lot of time to figure out how to do it and work out the details; you know, just perfect. Our approach, which uses computer technology and good old metalworking, is a combination of forging and aerospace technology.”

According to him, it is difficult to manufacture something so large and heavy with high precision. The largest slabs averaged 7 feet wide and 11 feet long and weighed 1,500 pounds.

“Doing all the CAD work and creating the actual shop drawings for this product was a big project in itself,” says Silva. “We use computer technology to measure the plates and accurately evaluate their shape and curvature so that they fit together correctly.

“We did a computer simulation and then took it apart,” Silva said. “I used my experience in shell building and figured out how to split the mold so that the seam lines work so we can get the best quality results.”

Some plates are square and some are pie-shaped. The closer they are to a sharp transition, the more they are pie-shaped and the larger the radius of the radial transition. At the top they are flatter and larger.

Plasma cutting 1/4 to 3/8 inch thick 316L stainless steel is tough enough on its own, Silva says. “The real challenge was to give the huge plates a fairly precise curvature. This was done by very precise shaping and manufacturing of the rib system of each plate. This allowed us to accurately determine the shape of each plate.”

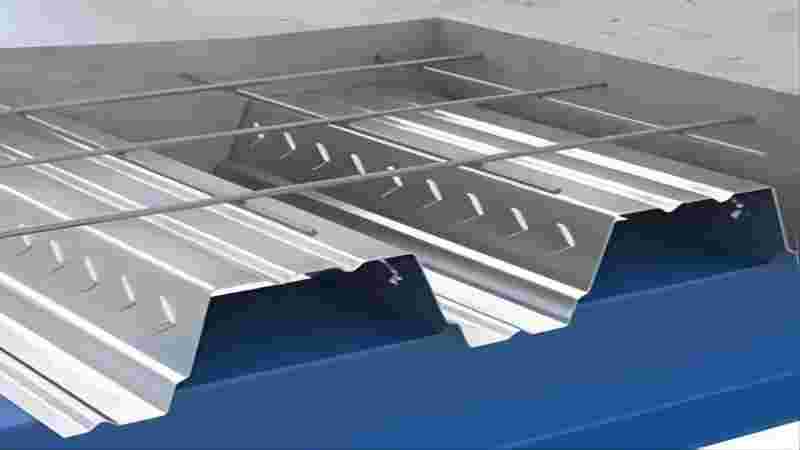

The sheets are rolled on 3D rolls designed and manufactured by PSI specifically for rolling these sheets (see Fig. 1). “It’s kind of a cousin of the English ice rink. We roll them using a technique similar to making wings,” says Silva. Bend each sheet by moving it back and forth on the rollers, adjusting the pressure on the rollers until the sheet is within 0.01″ of the desired size. According to him, the required high precision makes it difficult to form the plates smoothly.

The welders then weld the bent plate to the internal structure of the ribbed system using flux cores. “In my opinion, flux absorption is a really great way to create structural welds in stainless steel,” explains Silva. “It delivers high quality welds, is very production oriented and looks great.”

The entire surface of the boards is sanded by hand and machined to cut them to the required thousandth of an inch precision so that they fit together perfectly (see Figure 2). Verify dimensions with accurate measuring and laser scanning equipment. Finally, the board is polished to a mirror finish and covered with a protective film.

About one third of the panels, together with the base and internal structure, were installed in a trial assembly before the panels were shipped from Auckland (see figures 3 and 4). A hanging procedure for the plates was planned and welds were made on some of the smaller plates to hold them together. “So when we put it together in Chicago, we knew it would fit,” Silva said.

Temperature, time and vibration of the trolley can cause the rolled product to loosen. The ribbed mesh is designed not only to increase the rigidity of the board, but also to keep the shape of the board during transport.

Therefore, the plates are subjected to heat treatment and cooling in order to relieve material stresses by reinforcing the mesh from the inside. To further prevent damage during shipping, brackets were made for each board and loaded into containers about four at a time.

The containers were then loaded onto semi-trailers, about four at a time, and shipped to Chicago with PSI crews for installation with MTH crews. One is a logistician who coordinates transportation, and the other is the technical head of the site. He works daily with MTH staff and helps develop new technologies as needed. “Of course, he was a very important part of the process,” Silva said.

MTH President Lyle Hill says MTH Industries was originally tasked with anchoring the ethereal sculpture to the ground and installing the superstructure, then welding plates to it and doing the final sanding and polishing, with PSI providing technical guidance. Completing the sculpture meant art. Balance with practice, theory with practice, required time and planned time.

Lou Czerny, vice president of engineering and project manager at MTH, said he was fascinated by the project’s uniqueness. “To the best of our knowledge, several things have happened on this particular project that have not been done or considered before,” Czerny said.

But developing the first of its kind requires deft ingenuity on the spot to respond to unforeseen problems and answer questions that arise along the way:

How do you install 128 car-sized stainless steel panels on a permanent superstructure with care? How to solder giant flexbeans without relying on it? How to get into a weld without being able to weld from the inside? How to achieve the perfect mirror finish of stainless steel welds in the field? What happens if lightning strikes him?

Czerny said the first indication that this would be an exceptionally challenging project was when construction and installation of the 30,000-pound platform began. Steel structure supporting the sculpture.

Although the fabrication of the high zinc structural steel supplied by PSI to assemble the base of the substructure is relatively simple, the substructure is located halfway between the restaurant and halfway through the car park, each at a different height.

“So the base is kind of cantilevered, wobbly at one point,” Czerny said. “Where we installed a lot of this steel, including the beginning of the actual slab work, we actually had to drive the crane into a 5-foot-deep hole.”

Czerny said they used a very sophisticated anchoring system, including a mechanical pretensioning system similar to that used in coal mining and some chemical anchors. Once the steel substructure is anchored in concrete, the superstructure must be installed to which the shell will be attached.

“We started by installing a truss system with two large 304 stainless steel O-rings—one at the north end of the structure and one at the south end,” Czerny says (see Figure 3). The rings are fastened with intersecting tubular trusses. The ring core subframe is sectioned and bolted in place using GMAW and electrode welding reinforcements.

“So there is this massive superstructure that no one has ever seen; it’s all for the structural framework,” Czerny said.

Despite the best efforts in designing, engineering, fabricating and installing all the components needed for the Oakland project, the sculpture was unprecedented, and new paths are always accompanied by burrs and scratches. Similarly, pairing one company’s manufacturing concepts with another’s is not as easy as passing the baton. In addition, the physical distance between sites results in delivery delays, making some on-site production logical.

“Even though the assembly and welding procedures were pre-designed in Auckland, the actual site conditions required everyone to be creative,” Silva said. “And the union staff is really great.”

For the first few months, MTH’s main job was to determine what was required for a day’s work, and how best to fabricate some of the components required to build the subframe, as well as some of the struts, “shocks”, arms, pins, and, like Hill said, pogo sticks. were needed to create a temporary siding system.

“It’s a continuous process, designing and manufacturing on the fly to keep everything moving and getting to the field quickly. We spend a lot of time sorting what we have, in some cases redesigning and redesigning, and then we make the necessary parts.

“Just Tuesday we’ll have 10 things we need to have on the field on Wednesday,” Hill said. “We have a lot of overtime and most of the work on the shop floor is done in the middle of the night.”

“Approximately 75 percent of siding assemblies are made or modified on site,” Czerny says. “There were a couple of times we did it 24 hours a day. I was in the store until 2 or 3 in the morning and came home at 5:30 in the morning, took a shower, took the material, still wet. ”

The MTN temporary suspension system used to assemble the hull consists of springs, struts and cables. All joints between the plates are temporarily fastened with bolts. “So the whole structure is mechanically connected, suspended from the inside by 304 trusses,” Czerny said.

We started with the dome at the base of the navel sculpture – “the navel inside the navel.” The dome is suspended from the trusses using a temporary four-point suspension spring support system, consisting of hangers, cables and springs. As more boards are added, the springs become a “gift,” Czerny said. The springs are then adjusted based on the additional weight of each plate to balance the entire sculpture.

Each of the 168 boards has its own four-point suspension and spring system, so they are individually supported in place. “The idea is not to overstress either of the joints as they are connected with a 0/0 gap,” Czerny says. “If the board hits the board underneath it can lead to warping and other problems.”

A testament to the precision of the PSI is its excellent fit with virtually no backlash. “PSI did a fantastic job making these tablets,” said Czerny. “I give them credit because, in the end, he really fit. The fit was really good which is fantastic for me. We are talking literally about thousandths of an inch. .”

“When they finished the assembly, a lot of people thought it was done,” says Silva, not only because of the tight seams, but also because the fully assembled part and its carefully polished panels did the trick. its surroundings. But the butt seam is visible, liquid mercury has no seams. In addition, the sculpture still needed to be fully welded to maintain its structural integrity for future generations, Silva said.

Completion of Cloud Gate had to be delayed during the park’s grand opening in the fall of 2004, so omphalus was a GTAW blot, which is why it stuck for months.

“You could see little brown dots all around the structure that were TIG welds,” Czerny said. “We started pitching tents again in January.”

“The next big production challenge for this project was welding seams without loss of form accuracy due to weld shrinkage,” said Silva.

According to Czerny, plasma welding provided the necessary strength and rigidity with minimal risk to the sheet. A mixture of 98% argon and 2% helium is the best at reducing fouling and improving melting.

The welders used a keyhole plasma welding method using a Thermal Arc® power source and a special tractor and torch assembly designed and used by PSI.

Post time: Feb-04-2023