In the world of gutter installation, the steel rain gutter cold roll forming machine has emerged as a game-changer. This advanced piece of equipment revolutionizes the process of manufacturing steel rain gutters, ensuring unrivaled precision, efficiency, and durability. In this comprehensive article, we will delve into the intricate details of this remarkable machine, exploring its functionality, advantages, and how it contributes to producing top-quality rain gutter systems.

1. Understanding the Steel Rain Gutter Cold Roll Forming Machine:

1.1 The Role of Cold Roll Forming:

The steel rain gutter cold roll forming machine uses a cold roll forming process to transform flat steel sheets into seamless gutter profiles. Unlike traditional methods, this machine operates at room temperature, eliminating the need for excessive heat, ensuring structural integrity and superior performance.

1.2 Precision Design and Functionality:

This ingenious machine incorporates a series of precisely engineered rollers and tooling sets, specifically designed to shape the steel sheets with utmost accuracy. Each roller imparts a specific contour to the metal, ensuring consistent dimensions and minimizing material waste.

2. Unraveling the Advantages of the Steel Rain Gutter Cold Roll Forming Machine:

2.1 Enhanced Efficiency:

The cold roll forming process employed by this machine boasts remarkable productivity, allowing for high-speed operation and rapid production of steel rain gutters. With superior efficiency, manufacturers can meet increasing demand while reducing costs and resources.

2.2 Unmatched Durability:

Thanks to the cold roll forming technique, the resulting rain gutter profiles exhibit exceptional strength and durability. This resilience ensures prolonged service life, even in the harshest weather conditions, making them an ideal choice for residential, commercial, and industrial applications.

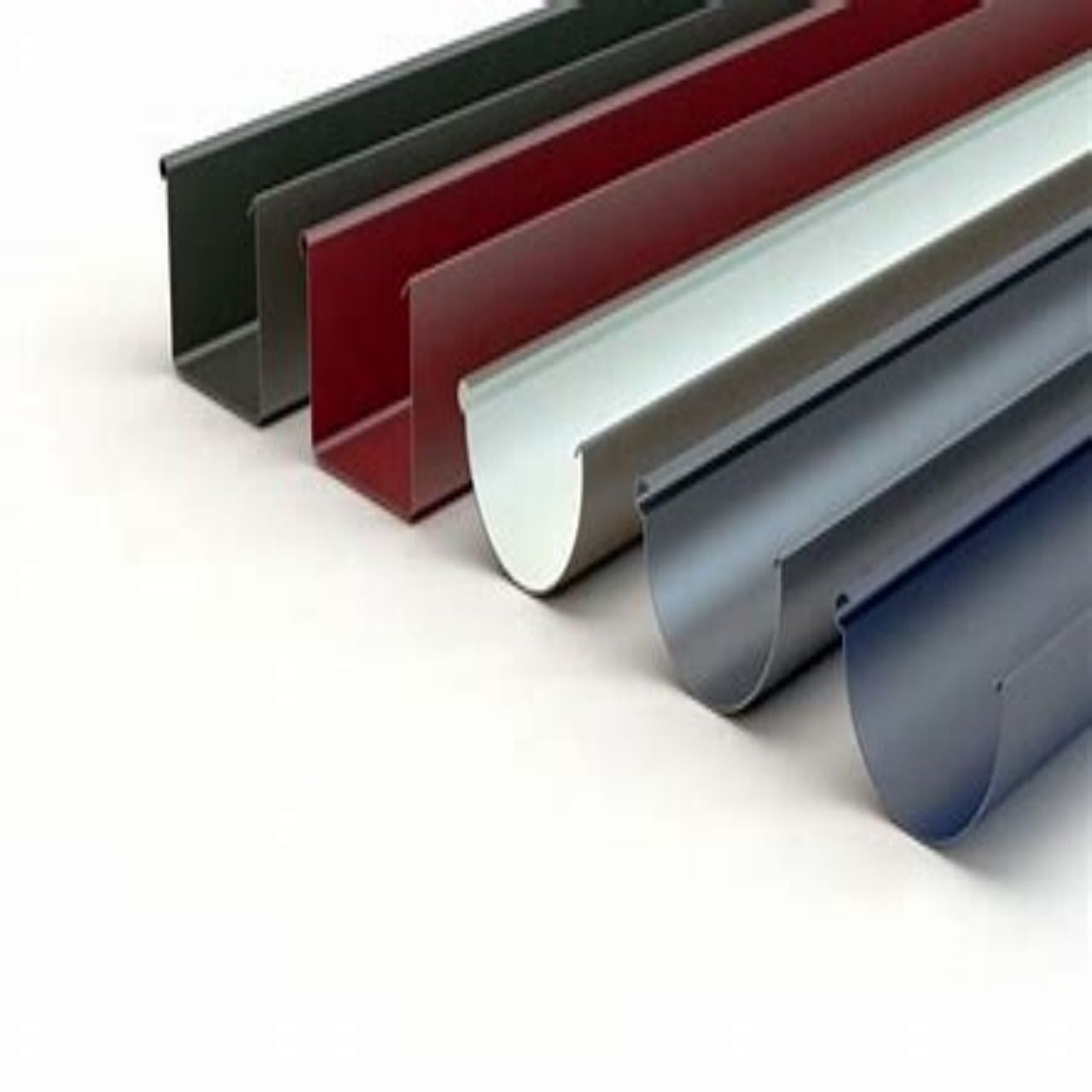

2.3 Customization and Flexibility:

The steel rain gutter cold roll forming machine empowers manufacturers to create gutters of various lengths, widths, and profiles, catering to specific architectural requirements. Furthermore, customization options such as color coatings and finishes add aesthetic appeal, enhancing the overall curb appeal of any structure.

3. The Process of Manufacturing Steel Rain Gutters Using the Cold Roll Forming Machine:

3.1 Material Selection:

Manufacturers carefully choose high-quality, corrosion-resistant steel sheets to guarantee long-lasting performance. The use of robust materials ensures that the rain gutters withstand the test of time and effectively divert rainwater away from the structure.

3.2 Roll Forming Procedure:

The steel sheets are fed into the cold roll forming machine in a continuous process. The machine’s rollers and tooling sets meticulously shape the steel, forming precise profiles that match the predetermined gutter design.

3.3 Additional Processes:

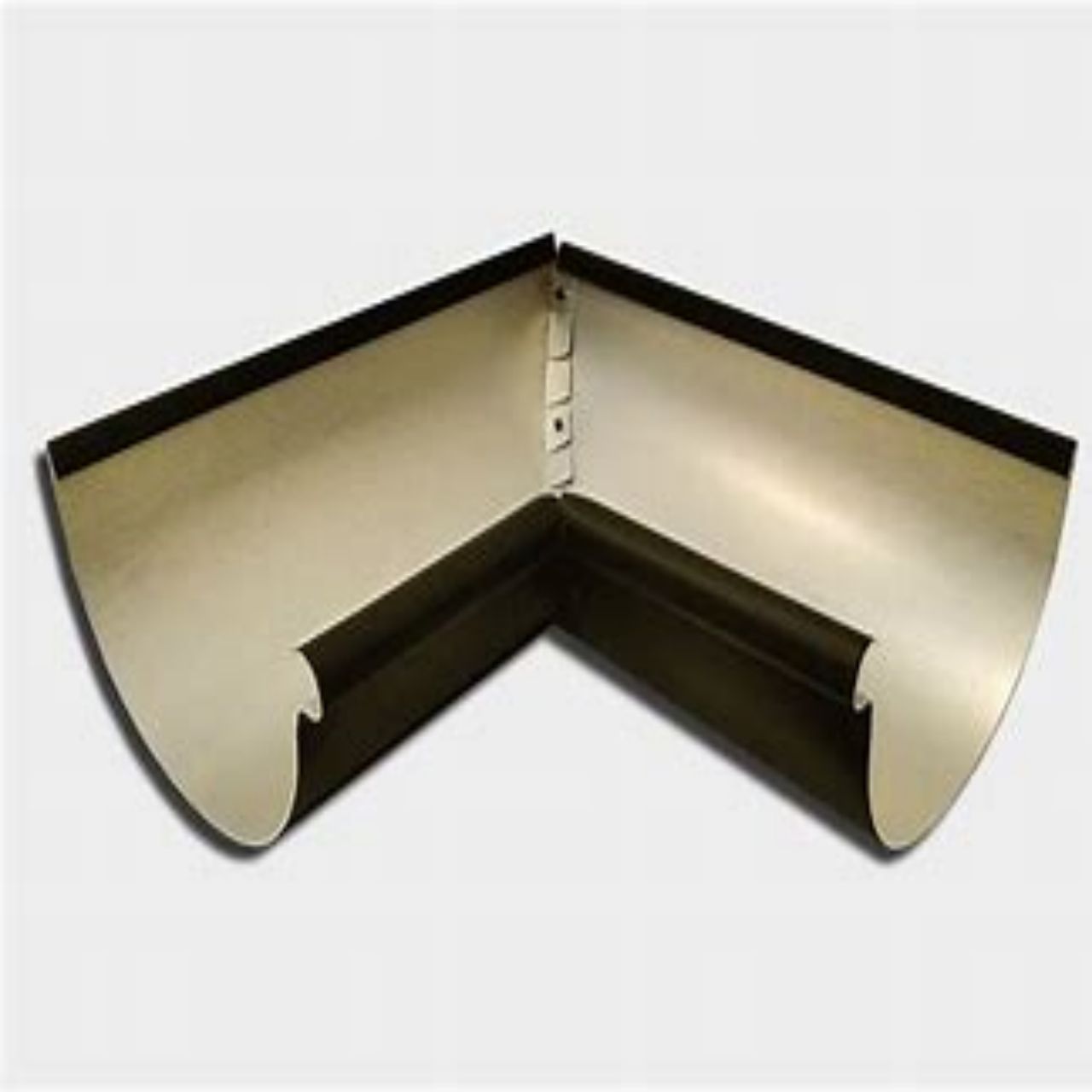

To further enhance the gutter’s functionality and appearance, manufacturers can incorporate additional features during the roll forming process. These can include flanges, hems, perforations, or even embossed patterns, offering both practical and aesthetic benefits.

4. The Implications on the Rain Gutter Industry:

The advent of steel rain gutter cold roll forming machines has significantly impacted the rain gutter industry. With the ability to produce high-quality gutters efficiently, manufacturers can expand their product offerings, meet customer demands swiftly, and elevate the industry’s overall standards.

Conclusion:

The steel rain gutter cold roll forming machine has truly revolutionized the way steel rain gutters are manufactured. Its precision, efficiency, and durability set new benchmarks in the industry, allowing for the production of top-quality gutter systems. As this technology continues to evolve, it plays a pivotal role in constructing resilient, aesthetic, and functional rainwater management solutions that ensure the protection and longevity of structures worldwide.

Post time: Nov-01-2023