The advent of steel sheet wall panel roll forming machines has revolutionized the construction industry, providing a game-changing solution for efficiently producing high-quality and durable steel panels. This advanced technology has significantly streamlined the manufacturing process, offering numerous benefits to builders, contractors, and architects worldwide. In this comprehensive article, we delve into the intricacies of steel sheet wall panel roll forming machines, exploring their functionality, advantages, and the impact they have on the construction landscape.

Understanding the Steel Sheet Wall Panel Roll Forming Machine:

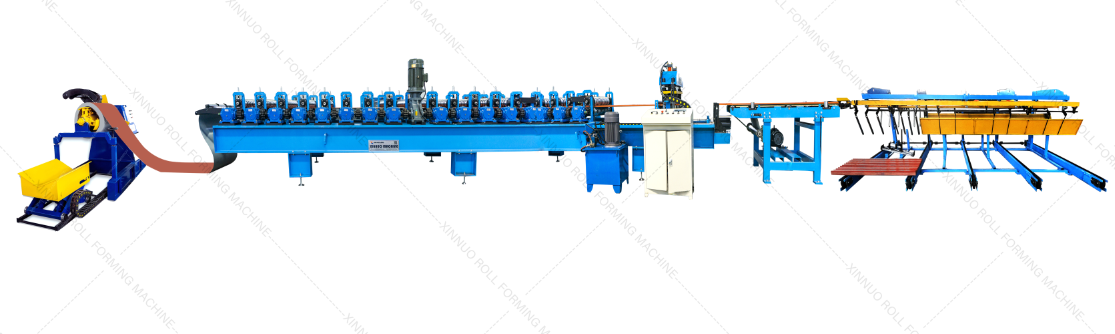

A steel sheet wall panel roll forming machine utilizes a continuous and automated process to transform flat steel sheets into perfectly shaped wall panels. The machine consists of various components, including decoilers, feeders, roll formers, cut-off systems, and stackers, all working in perfect synchronization to produce precise and consistent wall panels. This sophisticated machinery is designed to meticulously handle varying specifications, ensuring customized solutions for different construction projects.

Unveiling the Benefits:

1. Enhanced Efficiency: By automating the production process, steel sheet wall panel roll forming machines eliminate the need for manual labor, significantly increasing production efficiency. These machines can produce large quantities of panels in a short span of time, enabling builders to meet tight construction deadlines.

2. Consistency and Precision: The advanced technology employed by these machines ensures consistent production of high-quality and accurately shaped wall panels. Each panel is manufactured to perfection, guaranteeing uniformity and eliminating variations that may arise with traditional panel production methods.

3. Diverse Design Flexibility: Steel sheet wall panel roll forming machines enable the creation of wall panels in various designs, sizes, and shapes. Builders and architects can easily adapt to different project requirements, accommodating specific architectural styles and aesthetic preferences.

4. Cost Savings: With reduced reliance on manual labor, steel sheet wall panel roll forming machines can significantly lower labor costs. Moreover, their precise material utilization and minimized scrap generation contribute to overall cost savings in the construction process.

5. Durability and Strength: Steel sheet wall panels produced by roll forming machines boast exceptional durability, ensuring prolonged structural integrity. These panels possess higher load-bearing capacities, enhanced resistance to weather elements, and increased fire resistance, making them a preferred choice for modern construction projects.

Applications and Industry Impact:

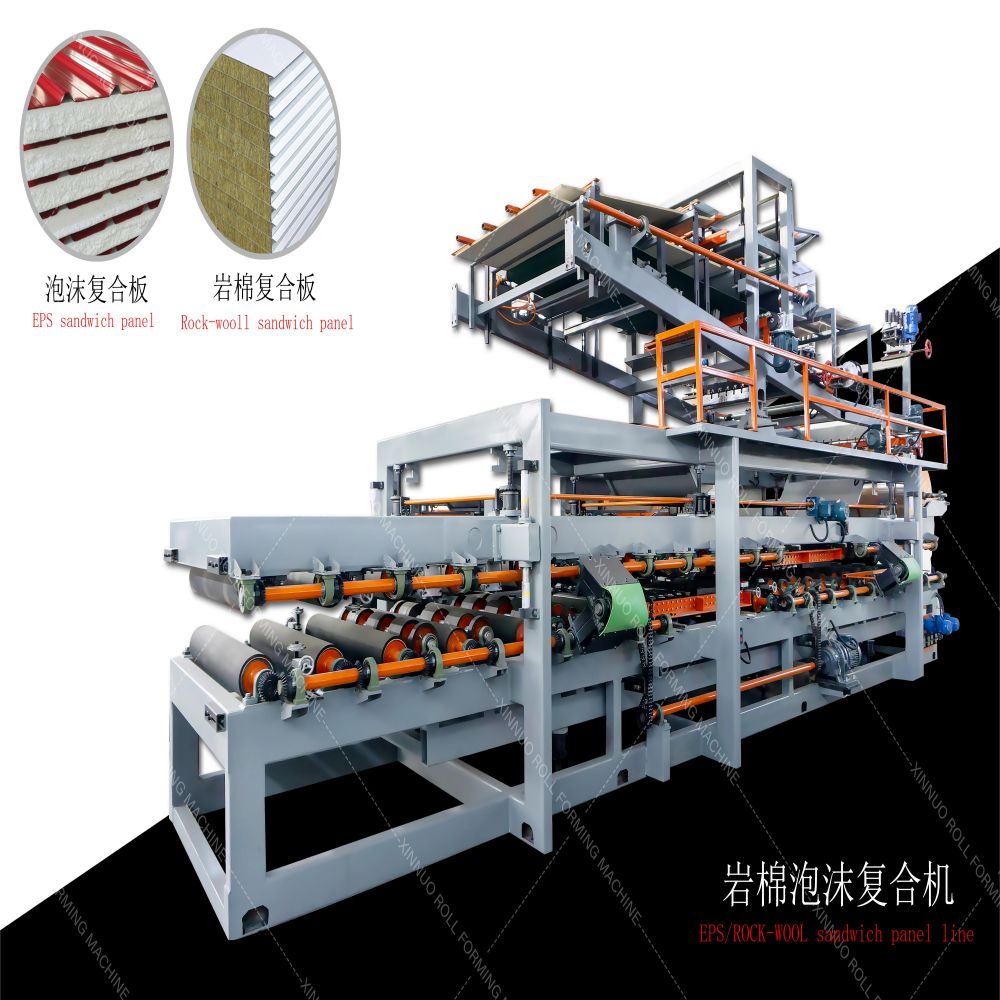

The applications of steel sheet wall panel roll forming machines are vast and diverse. From residential and commercial buildings to industrial warehouses and agricultural facilities, these machines enable the seamless production of panels for a wide range of construction projects. Furthermore, the utilization of steel sheet wall panels improves the overall sustainability of buildings by reducing waste and enhancing energy efficiency.

Keywords: Advancements in Steel Sheet Wall Panel Roll Forming Machines, Industry Impact, Construction Efficiency, Design Flexibility, Cost Savings, Durability.

Conclusion:

Steel sheet wall panel roll forming machines have emerged as a game-changer in the construction industry, offering unparalleled efficiency, precision, and versatility. These machines have transformed the way wall panels are manufactured, impacting the industry at various levels. With their ability to consistently produce high-quality panels of diverse designs, these machines provide builders and architects with the means to bring their visions to life swiftly and economically. Embracing the power of steel sheet wall panel roll forming machines ensures enhanced construction efficiency, reduced costs, and a future of sustainable and durable structures.

Post time: Oct-14-2023