Introducing the innovative Xinnuo EPS/Rockwool Sandwich Panel Production Line, a cutting-edge solution revolutionizing the construction industry. This article delves into the intricate workings of this advanced machinery, exploring its components, operating processes, and the myriad benefits it offers. From enhancing energy efficiency to ensuring durability and cost-effectiveness, these panels have emerged as a go-to choice for architects, builders, and developers seeking sustainable building solutions. Join us on a journey through the world of EPS/Rockwool Sandwich Panel Production, where technology meets sustainability in the construction of tomorrow.

Introduction to Xinnuo EPS/Rockwool Sandwich Panel Production Line

Overview of Xinnuo Company

Welcome to the world of Xinnuo, where innovation meets efficiency in the realm of sandwich panel production. With a track record of excellence, Xinnuo is a company that stands out for its commitment to quality and cutting-edge technology.

Definition and Purpose of EPS/Rockwool Sandwich Panels

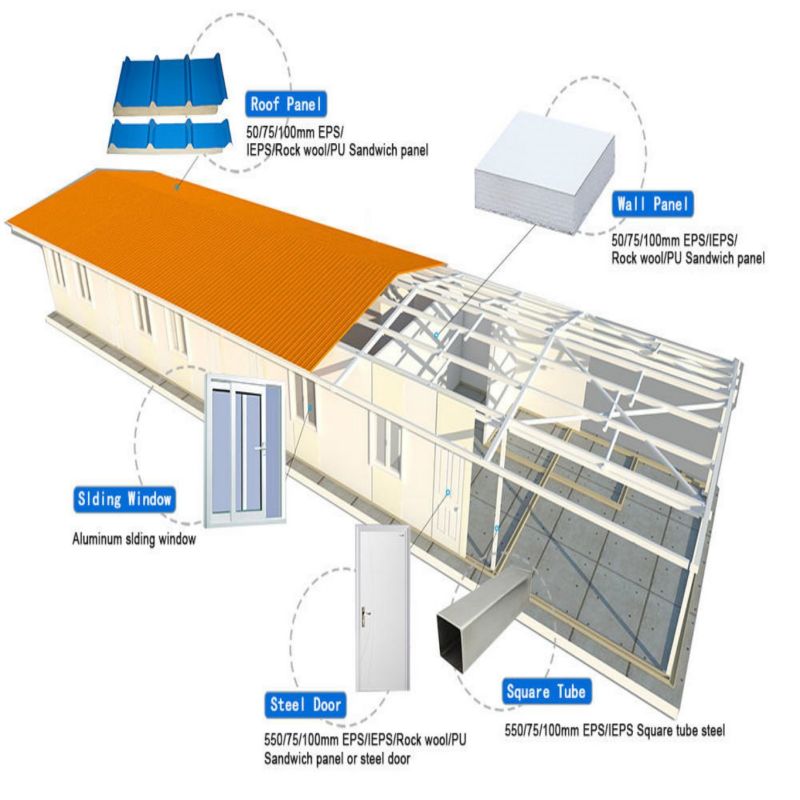

EPS/Rockwool sandwich panels are like the superheroes of building materials, combining the strength of steel with the insulation prowess of EPS or Rockwool. These panels are designed to provide thermal insulation, structural support, and fire resistance, making them a go-to choice for construction projects looking for durability and energy efficiency.

Components and Features of the Production Line

Key Components of the Production Line

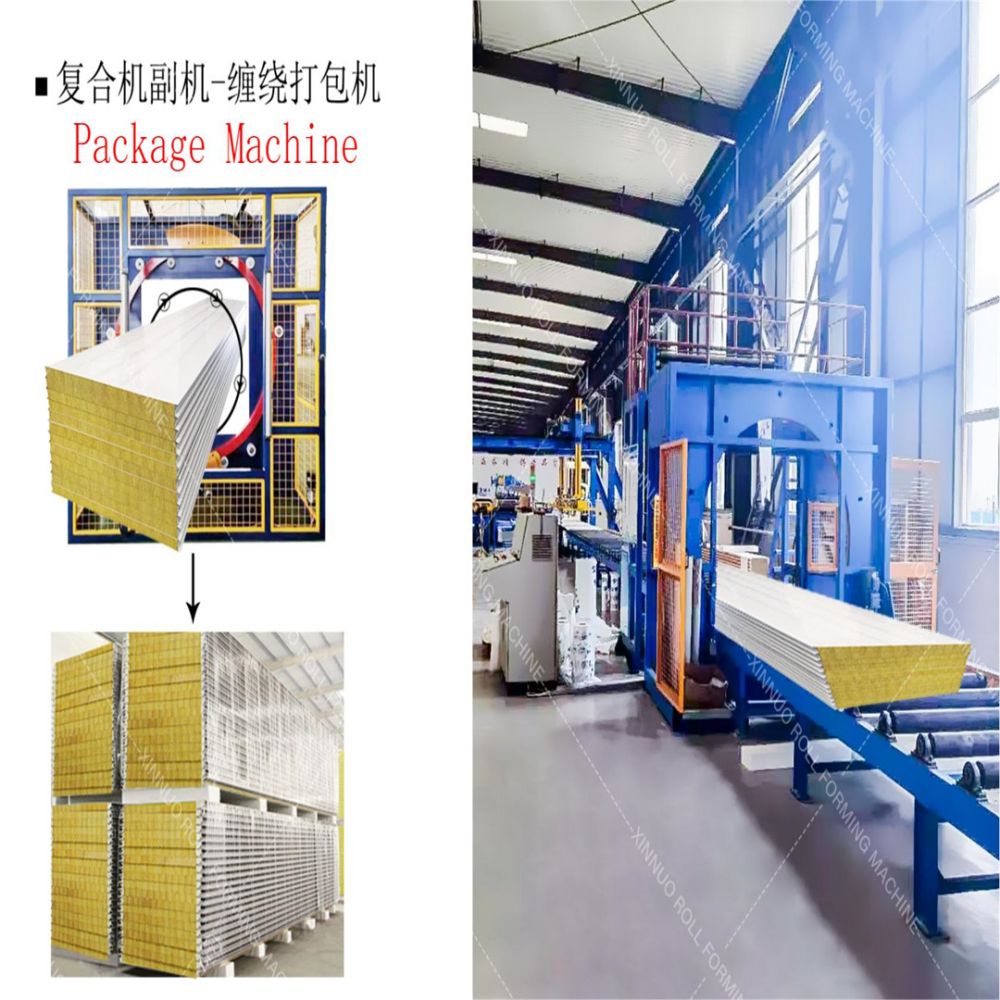

Picture this: a symphony of machinery working in harmony to create the perfect sandwich panel. Xinnuo’s production line boasts key components like roll forming machines, cutting systems, and laminating equipment, all coming together to craft panels that are as tough as they are thermally efficient.

Features and Specifications of the Machinery

Xinnuo’s machinery is not just your average Joe. With features like precision engineering, user-friendly interfaces, and high-speed production capabilities, this equipment is designed to take your sandwich panel game to the next level. Get ready to be wowed by the specifications that make Xinnuo’s production line stand out from the crowd.

Operating Process and Workflow

Step-by-Step Production Process

Curious about how the magic happens? The production process at Xinnuo is a well-oiled machine, with each step meticulously planned for maximum efficiency. From material preparation to panel cutting, every stage is a vital piece of the puzzle that leads to the creation of top-notch sandwich panels.

Workflow Efficiency and Optimization

Efficiency is the name of the game at Xinnuo. By streamlining workflows, optimizing processes, and embracing innovation, Xinnuo ensures that your sandwich panel production runs like a well-tuned sports car. Say goodbye to inefficiencies and hello to smooth sailing with Xinnuo’s workflow optimization strategies.

Benefits and Advantages of Using EPS/Rockwool Sandwich Panels

Insulation Properties and Energy Efficiency

When it comes to keeping things cozy, EPS/Rockwool sandwich panels have got your back. These panels offer top-notch insulation properties, ensuring that your building stays warm in the winter and cool in the summer. Say goodbye to sky-high energy bills and hello to a snug, energy-efficient space.

Cost-Effectiveness and Sustainability

Who says you can’t have your cake and eat it too? With EPS/Rockwool sandwich panels, you can enjoy cost savings and sustainability benefits all in one package. These panels are not only durable and long-lasting but also eco-friendly, making them a smart choice for the planet and your wallet. Say yes to sustainability without breaking the bank with Xinnuo’s sandwich panels.

Quality Control and Safety Measures

Quality Assurance Protocols

When it comes to ensuring top-notch quality in EPS/Rockwool sandwich panel production, Xinnuo doesn’t mess around. Their quality assurance protocols are tighter than your jeans after a holiday feast. From raw material inspection to final product testing, every step is scrutinized with the precision of a hawk eyeing its prey. You can trust that Xinnuo’s panels have been through more checks than your mom sneaking up on you while you’re on your phone past bedtime.

Safety Precautions and Guidelines

Workplace safety is no joke, and Xinnuo takes it seriously. They have more safety precautions than your grandma has pins in her sewing kit. From mandatory safety gear to emergency drills, they’ve got it all covered. You can sleep soundly knowing that Xinnuo’s production line is as safe as a panda in a bamboo forest.

Market Applications and Industry Trends

Diverse Applications of EPS/Rockwool Panels

EPS/Rockwool panels are like the chameleons of the construction world – they can adapt to almost any environment. From cold storage units to industrial buildings, these panels have more uses than your phone has apps. Xinnuo’s panels are as versatile as a Swiss Army knife, making them a go-to choice for a wide range of applications.

Emerging Trends in Sandwich Panel Manufacturing

The sandwich panel industry is evolving faster than a chameleon changing colors. With sustainability and energy efficiency taking the spotlight, manufacturers like Xinnuo are stepping up their game. From eco-friendly materials to innovative production techniques, the future of sandwich panel manufacturing is looking brighter than your neighbor’s Christmas lights.

Maintenance and Troubleshooting Guidelines

Routine Maintenance Procedures

Just like your car needs an oil change every now and then, Xinnuo’s production line requires regular maintenance to keep it running smoothly. From cleaning routines to system checks, following these maintenance procedures is key to ensuring your production line stays as sharp as a chef’s knife.

Common Issues and Solutions in Production Line Operation

No production line is immune to hiccups, but with Xinnuo’s troubleshooting guidelines, you’ll be back on track faster than you can say “EPS/Rockwool sandwich panel.” Whether it’s a glitch in the system or a misaligned component, these common issues and solutions will have you feeling more confident than a cat with nine lives. Remember, with Xinnuo by your side, no production problem is too tough to crack.In conclusion, the Xinnuo EPS/Rockwool Sandwich Panel Production Line stands as a beacon of innovation in the realm of construction materials. With its efficient workflow, quality control measures, and diverse market applications, this production line paves the way for a greener, more sustainable future in building design and construction. Embracing the benefits of these panels not only elevates the quality and efficiency of construction projects but also contributes to a more environmentally conscious industry. As we look towards the future, the versatility and reliability of EPS/Rockwool Sandwich Panels continue to shape the landscape of modern construction practices.

Frequently Asked Questions

1. What are the primary materials used in EPS/Rockwool Sandwich Panels?

2. How does the Xinnuo production line ensure quality control during the manufacturing process?

3. What are some of the key advantages of using EPS/Rockwool Sandwich Panels in construction projects?

4. Can the production line be customized to accommodate specific project requirements or panel specifications?

Post time: Mar-11-2024