What is the slitting machine divided into several types

Slitting machine, also known as slitting line, slitting machine, slitting machine, is a name for metal slitting equipment.

1. Purpose: It is suitable for longitudinal shearing of metal strips, and rewinding the slitted narrow strips into rolls.

2. Advantages: convenient operation, high cutting quality, high material utilization, and stepless speed regulation of the cutting speed.

3. Structure: It consists of unwinding (unwinding), leading material positioning, slitting and slitting, coiling (rewinding), etc.

4. Applicable materials: tinplate, silicon steel sheet, aluminum strip, copper, stainless steel sheet, galvanized sheet, etc.

5. Applicable industries: transformers, motors, home appliances, automobiles, building materials, packaging industries, etc.

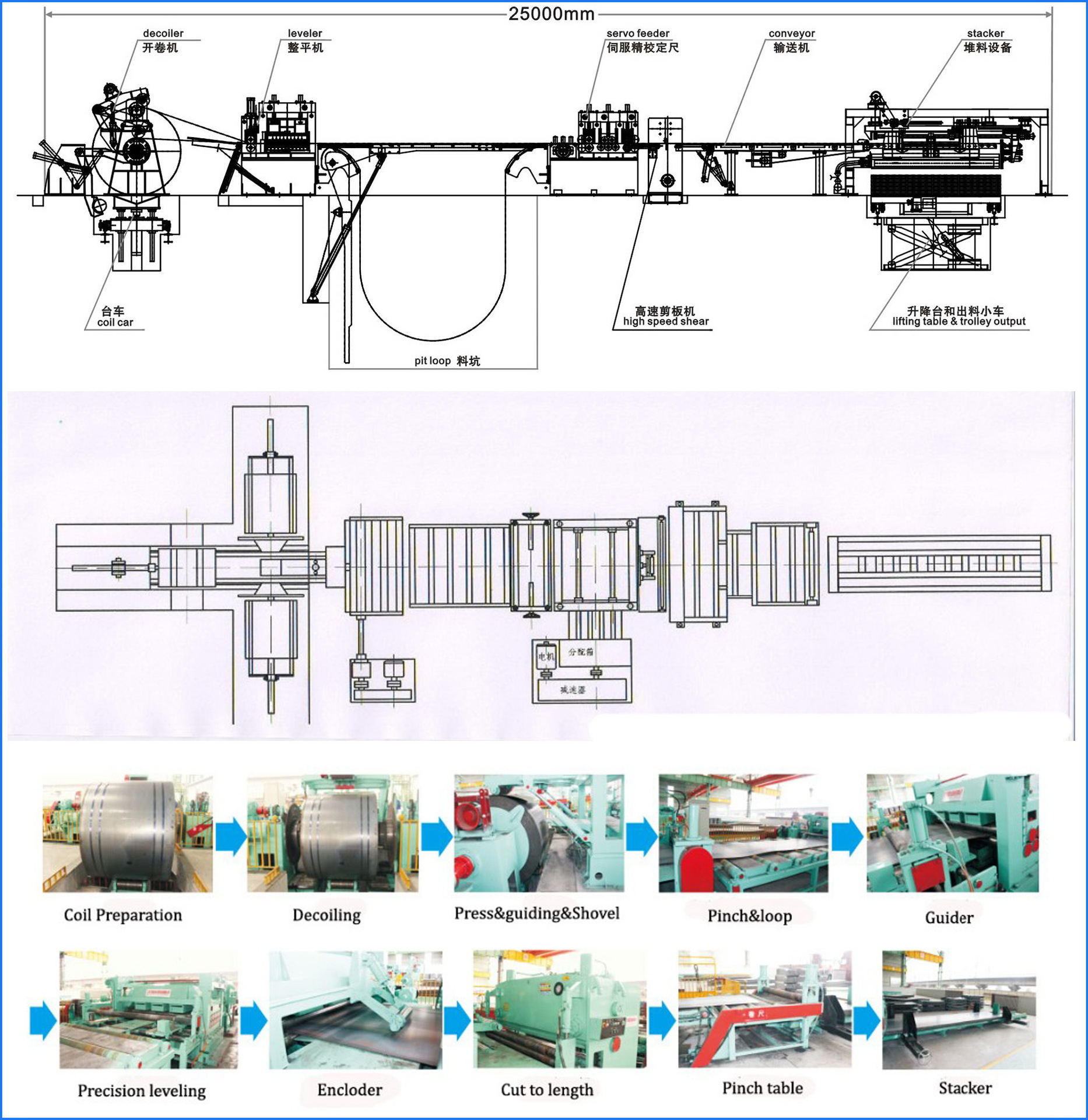

The sheet metal slitting machine(slitter, cut-to-length machine)

Slitting machine, also known as slitting line, slitting machine, slitting machine, is used for uncoiling, slitting, and winding metal coils into coils of the required width. It is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and various metal materials after surface coating.

1. Purpose: Suitable for longitudinal shearing of metal strips, and rewinding the slitted narrow strips into rolls.

2. Advantages: convenient operation, high cutting quality, high material utilization, and stepless speed regulation of the cutting speed.

3. Structure: It consists of unwinding (unwinding), leading material positioning, slitting and slitting, coiling (rewinding), etc.

4. Applicable materials: tinplate, silicon steel sheet, aluminum strip, copper, stainless steel sheet, galvanized sheet.

5. Applicable industries: transformers, motors, home appliances, automobiles, building materials, packaging industries, etc.

Slitting machines are divided into parallel blade shears and oblique blade shears. Parallel blade shears. The two blades of this shearing machine are parallel to each other. It is usually used for transverse shearing of blooms (square, slab) and other square and rectangular section billets, so it is also called billet shearing machine. This type of shearing machine sometimes also uses two forming blades to cold cut rolled parts (such as round tube blanks and small round steel, etc.), and the shape of the blade is adapted to the cross-sectional shape of the cut-and-rolled part. Oblique blade shearing machine. The two blades of this shearing machine, the upper blade is inclined, the lower blade is horizontal, and they are at a certain angle to each other. The inclination of the upper blade is 1°~6°. This kind of shearing machine is often used for cold shearing and hot shearing of steel plates, strip steels, thin slabs and welded pipe billets. Sometimes it is also used to cut small steel into bundles.

When rolling open-web window materials, an oblique blade shearing machine is commonly used to cut the head and tail of the strip (when the used strip is not trimmed), for joining and welding into large coils of steel.

The oblique blade shearing machine makes the upper blade inclined and the lower blade horizontal. Its purpose is to reduce the length of shear contact with the piece to be cut, thereby reducing the shearing force and reducing the size of the shearing machine. , And simplify the structure. The main parameters of the oblique blade shearing machine are: maximum shearing force, blade inclination angle, blade length and cutting times. These parameters are determined according to the size and mechanical properties of the rolled piece

How are steel coils cut?

Slitting steel is essentially, a cutting process. Large rolls or coils of steel are cut lengthwise to create strips of metal that are narrower than the original in width. This is an automated process where the master coil is run through a machine that has very sharp rotary blades, one upper and one lower, often called knives.

While the knives, clearly, are key to the process the un-coiler, knives and re-coiler must all be aligned and set correctly (knife clearance and uncoil/recoil tension levels are critical) in order to avoid problems. Dull knives along with a bad set-up can lead to burred edges, edge wave, camber, crossbow, knife marks, or slit widths that don’t meet specs.

Another basic processing application is blanking. A blanking line will uncoil the material, level it, and cut it to a specified length and width. As a result, a blank normally goes directly into the manufacturing process without being re-sheared. In order to achieve the desired tolerance, blanking lines utilize a close tolerance feed system, side trimmers and in-line slitters.

Cut-to-length lines are generally thought of as systems that produce sheets. Sheets are cut to a standard size and typically re-sheared at the end user. In order to achieve flatness tolerances, cut-to-length equipment needs to have precision corrective levelers. These levelers elongate the steel beyond its yield point (the amount of stress the steel can take at the onset of permanent deformation) in order to remove internal stresses and produce a flat sheet.

coil cutting machine

Common Finishing Options in Steel Processing

The most common method of perforating metal uses a rotary pinned perforation roller. This is a large cylinder with sharp, pointed needles on the outside to punch holes into the metal. As the sheet metal is run across the perforation roller, it rotates, continuously punching holes in the passing sheet. The needles on the roller, which can produce a wide variety of hole sizes, are sometimes heated to simultaneously melt the metal which forms a reinforced ring around the perforation.

Pre-painting steel is common customer need. Pre-painted steel is produced by a direct application of paint (after cleaning and priming) onto steel sheet in a coil-coating line. Coil-line painting can be used to apply a paint coating directly on the uncoated steel sheet or on metallic-coated steel sheet, including galvanized. Pre-painting increases the anti-corrosive properties of steel.

A focus on slitting lines

A common theme among fabricators and service centers is that slitting lines has become a commodity process with very low margins. Considering the staggering amount of manufacturing that has moved overseas recently, it follows that too many slitting lines in the U.S. are chasing too small a market—or, simply put, the slitting market has too much capacity. Carbon steel has been hit the hardest because it requires less advanced technology and often can be processed using unskilled, low-cost labor.

To maintain a manufacturing sector in this country, industry must continually improve in efficiency. Manufacturers and processors can and should specify new machines that run at high speeds and allow quick setups, which are two essential ingredients for efficient operation. If a new slitting line is not in the cards, however, many existing slitting line components can be upgraded to improve efficiency.

Choosing the right components does not necessarily mean choosing the most expensive ones. Coil processors should choose components that match the type of products run, the frequency of setup changes, and the labor available to operate the line. Some of the aspects that affect slitting line efficiency are entry coil storage; coil inside diameter (ID) changes; slitter tooling changeover; scrap handling; and strip tension.

A good entry coil storage system can improve efficiency by reducing line downtime and by allowing efficient use of overhead cranes. The ability to stage multiple coils is crucial because it prevents waiting at the line, and it allows the crane operator to retrieve and load coils whenever it is convenient, not when it is necessary. Common coil storage devices are turnstiles, saddles, and turntables.

Turnstiles with four arms are suitable for many slitting line applications. Because they rotate, they allow the line operator to select any coil in any order. However, they support coils by the ID, and may damage thin, heavy coils. Also, it can be difficult to load small-ID coil

Like it or not, slitting lines, like many manufacturing operations, are now competing with low-cost operations on a global scale. Excellent quality and service alone do not guarantee profit or survival. To remain competitive, coil processors must operate their slitting lines at peak efficiency. Keeping a close eye on the main areas that affect slitting line efficiency, and using the most suitable equipment in those areas, combined with proper staffing and training, can help coil processors remain competitive in an increasingly competitive industry.

flying shear cut to length line

Sheet metal slitting machine slitter cut to length machine with cross cutting knife

Tips about metal slitting machine

Metal slitting machine equipment is divided into three categories: simple metal slitting machine, hydraulic semi-automatic metal slitting machine, automatic metal slitting machine.

Metal slitting machine features: It is composed of decoiler (discharger), leveling machine, guide positioning, slitting equipment (slitting equipment), winding machine, etc. It cuts wide material coils into narrow coils of a certain size according to the set length direction to prepare for other processing procedures in the future.

The function of the metal slitting machine: The slitting material of the metal slitting machine is mainly metal coils, such as strip steel, stainless steel, etc., which slit the strip into a number of required specifications. It is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and all kinds of metal coils after surface coating.

Advantages of metal slitting machine: reasonable layout, simple operation, high degree of automation, high production efficiency, high working accuracy, and can process various cold-rolled, hot-rolled coils, silicon steel plates, stainless steel plates, color plates, aluminum plates and electroplated or All kinds of metal coiled plates after coating.

The components of the metal slitting machine: The metal slitting machine is mainly composed of a feeding trolley, a decoiler, a leveling machine, a slitting machine, a scrap winder, a tensioner, a winder, and a discharge device.

The structure of the metal slitting machine: the base is welded by section steel and steel plate, and is treated qualitatively.

Fixed archway, thickness 180mm-1 piece; movable archway thickness 100mm-1 piece; welded steel plate, aging treatment, precision processing by boring machine.

The movable arch is moved manually; the material of the sliding seat: QT600; the cutter shaft lifting wheel and worm pair are raised and lowered synchronously, the hand wheel is manually fine-tuned, and the lifting and returning accuracy is not more than 0.03mm.

Tool shaft: diameter φ120mm (h7), effective length of the tool shaft: 650mm, key width 16mm; material 40Cr forging, quenching and tempering HB240∽260, rough machining, intermediate frequency processing, grinding, hard chrome plating, and then grinding; the tool shaft does not run out Greater than 0.02mm, and the shoulder run out should not be greater than 0.01mm.

The rotation of the knife shaft is driven by universal joints, a synchronous gear box, and the power is driven by AC15KW frequency conversion speed regulation. Synchronous gearbox: steel plate welding, qualitative treatment, precision machining of bearing holes by boring machine, gears are forged with 40Cr, quenched and tempered HB247∽278, quenched HRC38∽45.

Knife shaft locking: The nut locks the tool, and the left and right nuts are rotated.

Types of slitting machine blades and scope of application

How to choose the slitting machine blade is determined according to the type and thickness of the slitting material. Generally, the slitting form of the slitting machine blade includes square knife slitting and round knife slitting.

coil slitter machine

1. Square knife slitting is like a razor, the blade is fixed on the knife holder of the slitting machine, and the knife is dropped during the operation of the material, so that the knife cuts the material longitudinally to achieve the purpose of slitting. Square slitting machine blades are mainly divided into single-sided blades and double-sided blades:

Single-sided blades are better when slitting thick films, because the hard blades are not prone to displacement when the slitter is high-speed. Single-sided blades are recommended for thicknesses between 70-130um.

Double-sided blades are softer and suitable for thinner materials. In this way, the flatness of the film edge is guaranteed, and the service life can be extended at the same time. Double-sided blades are recommended for thickness below 70um.

As far as the slitting method of the slitting machine is concerned, square knife slitting is generally divided into slot slitting and suspended slitting:

1) When the material is running on the grooved roller, the cutting knife is dropped into the groove of the grooved roller, and the material is cut longitudinally. At this time, the material has a certain wrap angle in the sipe roller, and it is not easy to drift.

2) Hanging slitting means that when the material passes between two rollers, the blade falls to cut the material longitudinally. At this time, the material is in a relatively unstable state, so the cutting accuracy is slightly worse than that of the die cutting. But this slitting method is convenient for knife setting and convenient for operation.

2. Round knife slitting mainly has two methods: upper and lower disc slitting and round knife squeezing slitting.

Circular knife slitting is the main slitting method for cutting thick film, composite thick film, paper and other materials. The thickness of the slitting material film is above 100um. It is recommended to use a round knife for slitting.

1) The upper and lower disc knife slitting methods are widely used, mainly including tangent slitting and non-tangential slitting.

Tangent cutting means that the material is cut in the tangential direction of the upper and lower disc cutters. This kind of slitting is more convenient for knife setting. The upper disc knife and the lower disc knife can be adjusted according to the cutting width requirements. Its disadvantage is that the material is easy to drift at the slitting position, so the accuracy is not high, and it is generally not used now.

Non-tangential slitting means that the material and the lower disc knife have a certain wrap angle, and the lower disc knife falls to cut the material. This cutting method can make the material less prone to drift, and the cutting precision is high. But it is not very convenient to adjust the knife. When installing the lower disc knife, the entire shaft must be removed. Circular knife slitting is suitable for slitting thicker composite films and papers.

2) The application of circular knife extrusion slitting in the industry is not very common. It is mainly composed of a bottom roller that is synchronized with the material speed and has a certain wrap angle with the material and a pneumatic slitting knife that is easy to adjust. This slitting method can slit relatively thin plastic films, as well as relatively thick paper, non-woven fabrics, etc. This is a more convenient way of slitting, and it is also a development direction of slitting machine slitting method.

Chequered Plate embossing machine

Chequered Plate embossing machine

Embossing is a metal forming process for producing raised or sunken designs or relief in sheet material by means of matched male and female roller dies, theoretically with no change in metal thickness, or by passing sheet or a strip of metal between rolls of the desired pattern.

Finally, there is fabrication, where steel is actual made into a part. Usually the metal is bent, or formed, into specific shapes to be used in manufacturing. Fabricating can create a piece that’s as complicated as a car body, or as simple as a panel.

Steel is strong, durable and the ideal material for everything from HVAC ductwork to railway cars. It takes steel processing and finishing to turn a master coil into a finished part.

Post time: Jan-05-2024