In today’s competitive market, businesses constantly strive to improve their production processes to meet customer demands efficiently. Xinnuo, a leading manufacturer in the metal forming industry, has introduced a groundbreaking innovation – the Xinnuo Metal Downspot Cold Roll Forming Line. This state-of-the-art machinery is set to revolutionize how metal downspouts are manufactured, offering unparalleled quality, precision, and productivity. Let’s delve into the remarkable features and advantages of this cutting-edge equipment.

In today’s competitive market, businesses constantly strive to improve their production processes to meet customer demands efficiently. Xinnuo, a leading manufacturer in the metal forming industry, has introduced a groundbreaking innovation – the Xinnuo Metal Downspot Cold Roll Forming Line. This state-of-the-art machinery is set to revolutionize how metal downspouts are manufactured, offering unparalleled quality, precision, and productivity. Let’s delve into the remarkable features and advantages of this cutting-edge equipment.

1. Unparalleled Precision and Versatility:

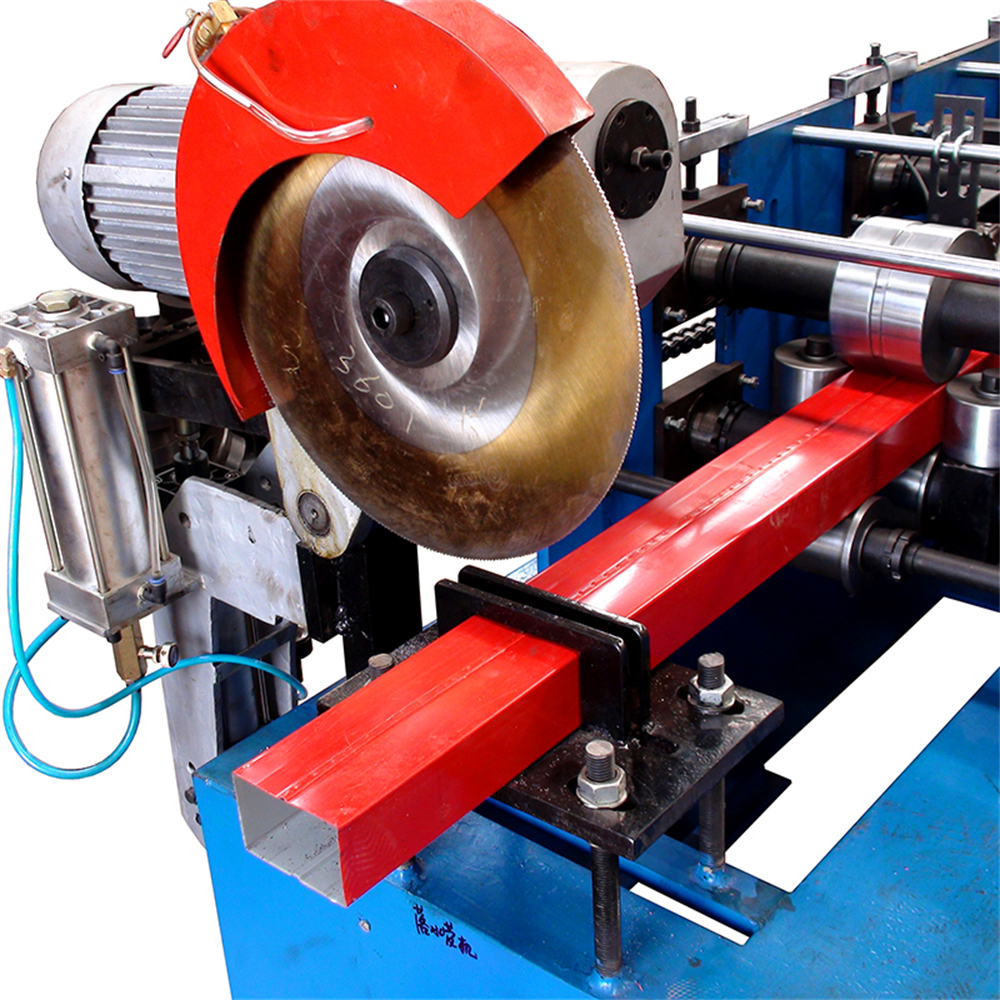

The Xinnuo Metal Downspot Cold Roll Forming Line stands out for its exceptional precision. Leveraging advanced technology, it ensures that every downspout produced adheres to precise specifications, eliminating any deviations or inconsistencies. This level of accuracy guarantees superior product quality, meeting and surpassing industry standards.

Additionally, the versatility of this equipment enables the production of metal downspouts in various profiles, shapes, and sizes. Customize your downspout designs effortlessly, allowing you to cater to diverse customer preferences and requirements.

2. Enhanced Efficiency and Productivity:

With Xinnuo’s Metal Downspot Cold Roll Forming Line, businesses can significantly enhance their efficiency and productivity. The intelligent automation system streamlines the production process, minimizing manual labor and reducing operational costs. This results in optimized production timelines and increased output, ensuring a competitive edge in delivering products within strict deadlines.

Furthermore, the high-speed capabilities of this machinery allow for continuous and uninterrupted production, eliminating wastage of valuable time during line adjustments. The quick changeover feature enables seamless transitions between different downspout profiles, yielding enhanced productivity and reducing downtime.

3. Robust Durability and Low Maintenance:

Understanding the significance of durable equipment in demanding manufacturing environments, Xinnuo has ensured that this cold roll forming line is built to last. Constructed with premium-grade materials and incorporating cutting-edge engineering, the machine offers exceptional reliability and longevity. It withstands rigorous production demands, reducing the need for frequent repairs or replacements.

Moreover, the low maintenance requirements of the Xinnuo Metal Downspot Cold Roll Forming Line contribute to operational efficiency. Minimized downtime due to maintenance tasks ensures uninterrupted productivity and maximized return on investment for businesses.

4. Innovations in Safety and Ergonomics:

Xinnuo prioritizes safety in its machinery design, and the Metal Downspot Cold Roll Forming Line is no exception. Equipped with advanced safety features, the machine provides a secure working environment, safeguarding operators from potential risks. From emergency stop buttons to protective guards, Xinnuo has covered all essential safety aspects, complying with industry regulations.

Additionally, the ergonomic design promotes convenience and ease of operation for workers. With user-friendly interfaces and intuitive controls, the machine minimizes operator fatigue and eliminates unnecessary complexities, resulting in improved efficiency and operator satisfaction.

Conclusion:

The Xinnuo Metal Downspot Cold Roll Forming Line is a game-changer in the metal forming industry. Its exceptional precision, versatility, efficiency, durability, and safety features set new benchmarks for downspout production. By investing in this cutting-edge equipment, businesses can elevate their manufacturing capabilities, surpass customer expectations, and gain a competitive advantage in the market. Experience the future of metal downspout manufacturing with Xinnuo, your trusted partner for excellence.

Post time: Dec-05-2023