I n the realm of roof sheet production, the emergence of advanced technology has greatly influenced the manufacturing process. One such innovation is the Cold Galvanizing Iron Sheet Roll Forming Making Machine. This cutting-edge technology has revolutionized the industry by streamlining the production of high-quality roof sheets. In this article, we will delve into the intricate details and benefits of this remarkable machine, highlighting its capabilities and the impact it has had on the roofing industry.

n the realm of roof sheet production, the emergence of advanced technology has greatly influenced the manufacturing process. One such innovation is the Cold Galvanizing Iron Sheet Roll Forming Making Machine. This cutting-edge technology has revolutionized the industry by streamlining the production of high-quality roof sheets. In this article, we will delve into the intricate details and benefits of this remarkable machine, highlighting its capabilities and the impact it has had on the roofing industry.

Understanding the Cold Galvanizing Iron Sheet Roll Forming Making Machine:

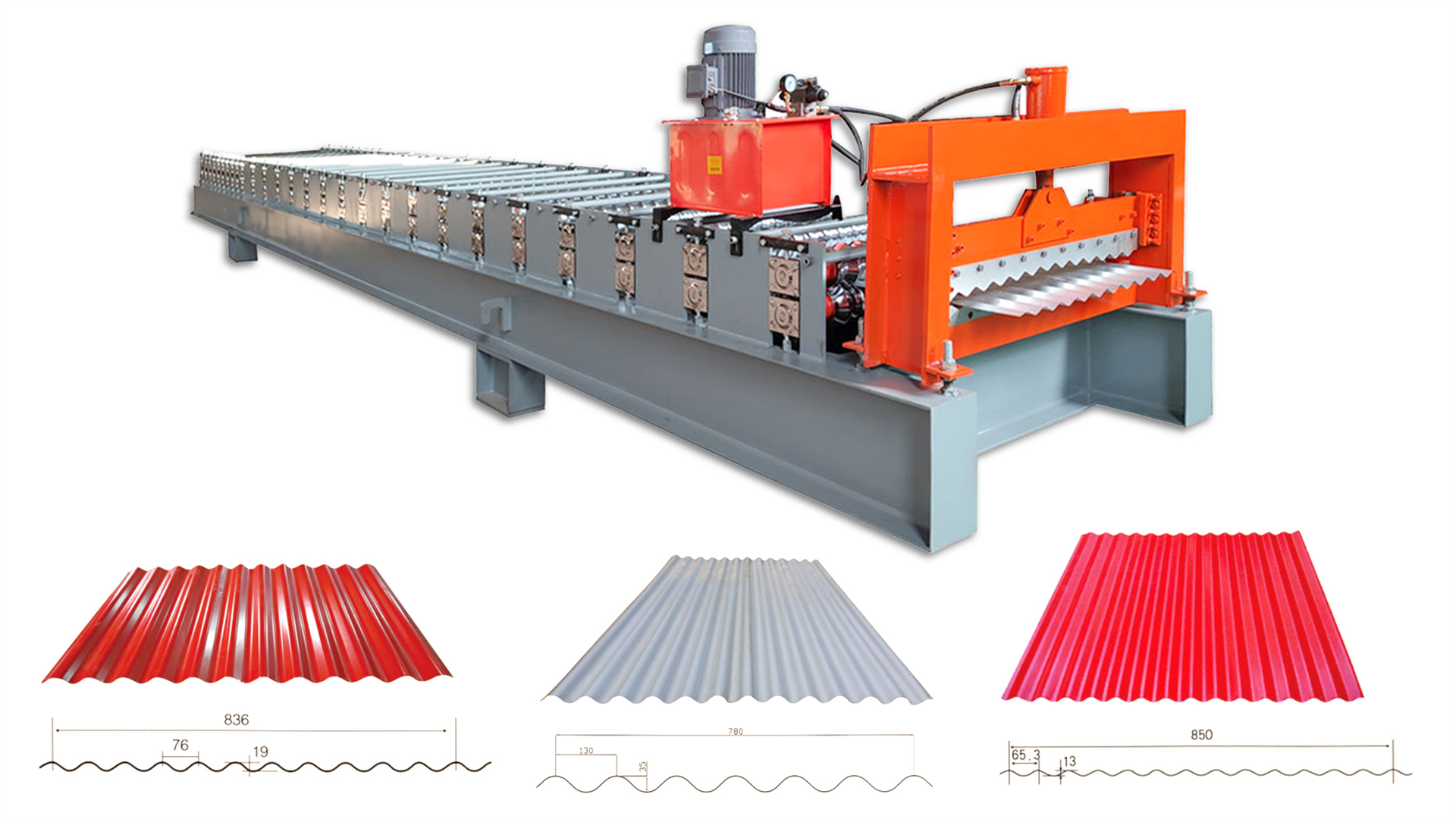

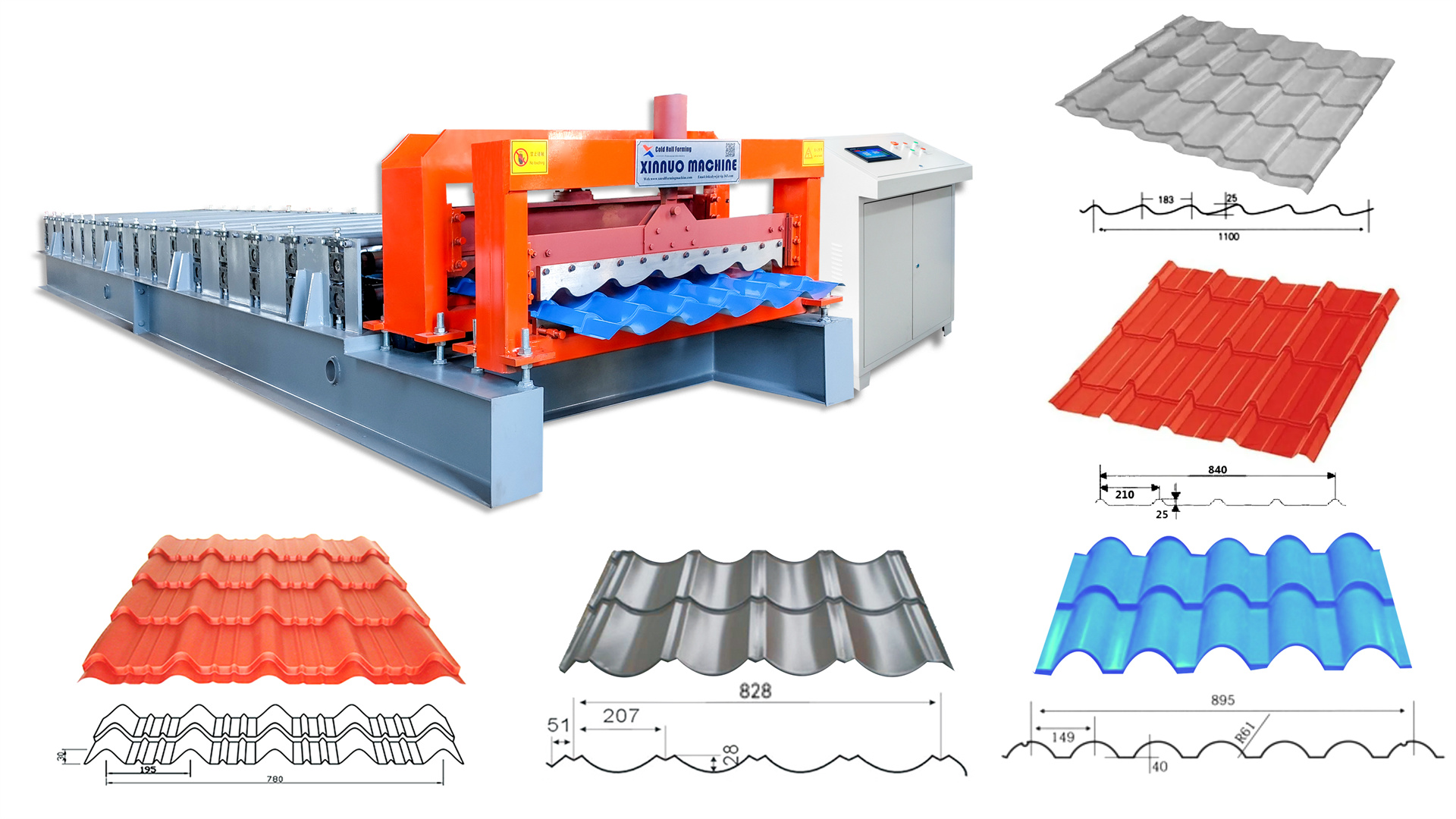

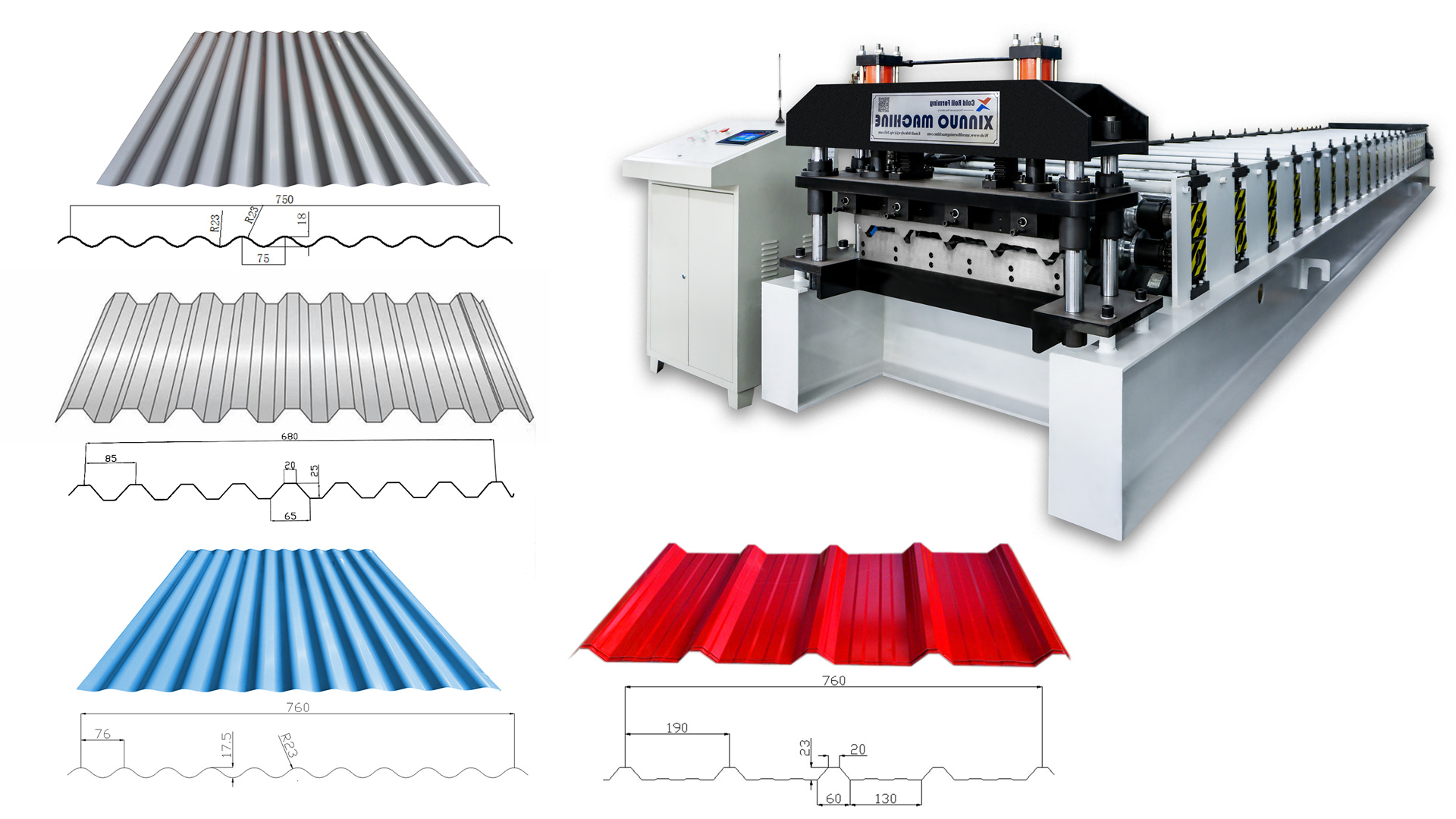

The Cold Galvanizing Iron Sheet Roll Forming Making Machine is a state-of-the-art device that utilizes high precision engineering to transform plain iron sheets into galvanized roof sheets. This machine operates by passing the iron sheets through a series of specially designed rollers, which gradually shape and mold the sheet into the desired profile. The process is carried out in a cold environment using galvanizing technology, ensuring optimum strength and longevity of the finished product.

Unmatched Precision and Efficiency:

One of the key advantages of the Cold Galvanizing Iron Sheet Roll Forming Making Machine is its remarkable precision and efficiency. Every component, from the rollers to the speed controls, is meticulously engineered to ensure seamless and accurate sheet formation. This eliminates any room for error, resulting in consistently high-quality roof sheets. Additionally, the machine boasts an exceptional production speed, enabling manufacturers to meet significant demands efficiently, saving time and enhancing productivity.

Quality Galvanizing for Durability:

Galvanizing, an important process in roof sheet production, involves applying a protective zinc coating to the surface of the iron sheets. The Cold Galvanizing Iron Sheet Roll Forming Making Machine excels in this aspect, ensuring the galvanizing process is executed flawlessly. The machine ensures an even and uniform coating, guaranteeing maximum protection against corrosion, rust, and the harshest weather conditions. By utilizing this advanced technology, manufacturers can provide durable roof sheets that stand the test of time, minimizing maintenance costs for end-users.

Versatility and Customization:

The Cold Galvanizing Iron Sheet Roll Forming Making Machine is highly versatile, capable of producing a wide range of roof sheet profiles. Whether it’s trapezoidal, corrugated, or any other profile, this machine can accommodate various designs effortlessly. The ability to meet diverse customer preferences and architectural requirements adds a significant advantage to manufacturers, enhancing their market competitiveness.

Cost-efficiency and Sustainability:

In today’s eco-conscious world, sustainability is a crucial factor. The Cold Galvanizing Iron Sheet Roll Forming Making Machine excels in this area as well. By utilizing cold galvanizing technology, energy consumption is minimized, making the machine highly energy-efficient. Furthermore, the durability and unparalleled protection provided by the galvanized sheets contribute to the reduction of waste, enabling a more sustainable approach to roof sheet production.

Conclusion:

The advent of the Cold Galvanizing Iron Sheet Roll Forming Making Machine has brought about a paradigm shift in the roofing industry. With its remarkable precision, efficiency, customization options, and cost-efficiency, this machine has effectively raised the standards of roof sheet production. Its impact on the market is undeniable, offering manufacturers a competitive edge, and end-users high-quality, long-lasting roofing solutions. Embracing this technology is not merely an option but a necessity for those seeking to excel in the ever-evolving roofing industry.

Post time: Dec-26-2023