Metal roofing sheet curving machines play a crucial role in shaping and bending metal sheets to fit the unique curves and angles required in various construction and design projects. These machines have evolved over time, offering a range of capabilities from manual operation to automated precision. Understanding the types, features, and operating procedures of metal roofing sheet curving machines is essential for achieving efficient and accurate results. In this article, we will explore the functionality, benefits, maintenance tips, and industry applications of these machines to provide a comprehensive overview of their significance in the metalworking sector.

**1. Introduction to Metal Roofing Sheet Curving Machines**

**Overview of Metal Roofing Sheet Curving Machines**

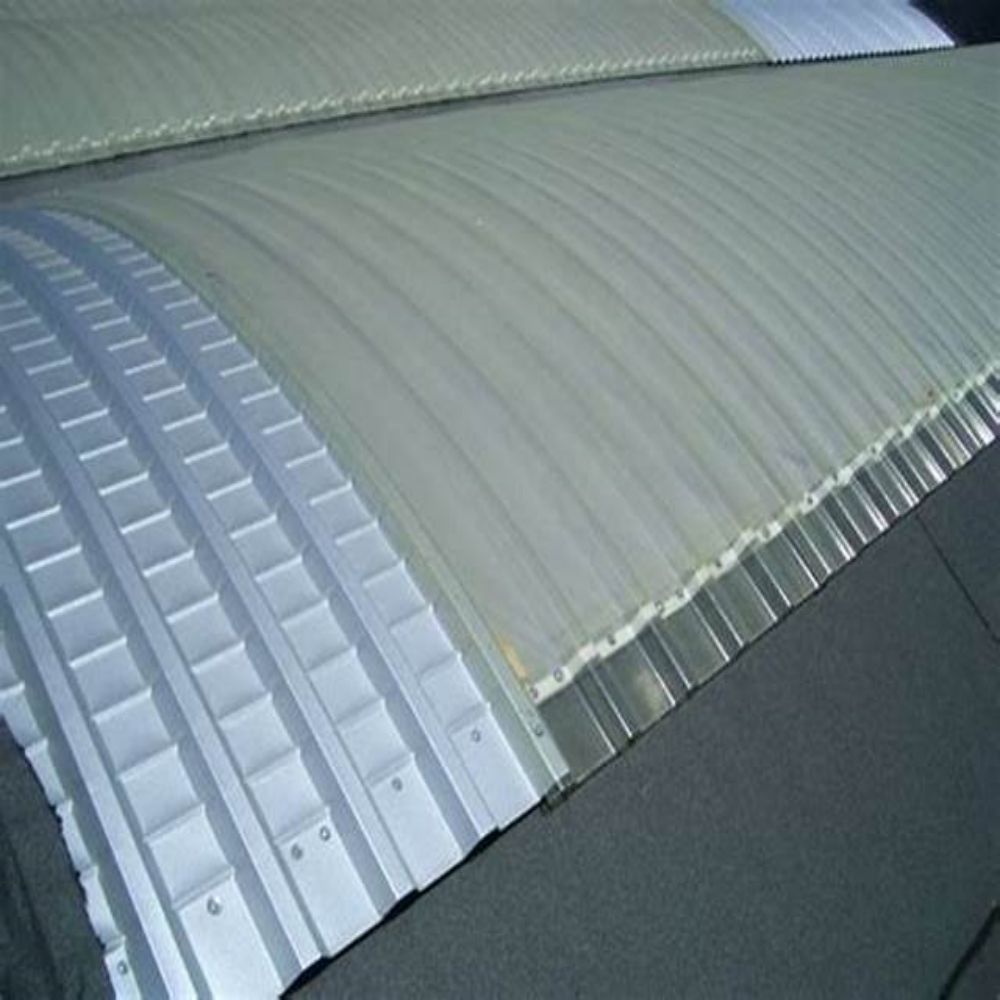

Metal roofing sheet curving machines are the unsung heroes of the construction industry, shaping metal sheets into elegant curves that not only look good but also provide structural stability to roofs. These machines are like the Michelangelo of the building world, sculpting metal with precision and finesse.

**Evolution of Metal Roofing Sheet Curving Technology**

From humble manual curving machines to sophisticated automated ones, the evolution of metal roofing sheet curving technology is a testament to human ingenuity. What started as basic tools operated by hand has now transformed into advanced hydraulic and automated machines that can curve metal sheets with the touch of a button.

—

**2. Types of Metal Roofing Sheet Curving Machines**

**Manual Curving Machines**

Manual curving machines are the OGs of the metal roofing sheet curving world. They require good old-fashioned elbow grease to operate but are perfect for those who appreciate a hands-on approach to craftsmanship.

**Hydraulic Curving Machines**

Hydraulic curving machines take things up a notch by using hydraulic power to curve metal sheets with ease. They are like the strongman of the curving machine family, effortlessly bending metal to their will.

**Automated Curving Machines**

Automated curving machines are the crème de la crème of the curving machine world. These high-tech marvels can curve metal sheets with precision and speed, making them ideal for large-scale roofing projects where time is of the essence.

—

**3. Key Features and Components of a Metal Roofing Sheet Curving Machine**

**Rolling Mechanism**

The rolling mechanism is the heart and soul of a metal roofing sheet curving machine. It exerts pressure on the metal sheet, gradually bending it into the desired curve. Think of it as the machine’s gentle yet firm embrace that transforms flat metal into a work of art.

**Adjustable Curving Settings**

Adjustable curving settings allow users to customize the curvature of the metal sheet to meet specific design requirements. It’s like having a magic wand that lets you create curves of all shapes and sizes with just a few adjustments.

**Safety Features**

Safety first, folks! Metal roofing sheet curving machines come equipped with safety features such as emergency stop buttons and protective guards to ensure the well-being of operators. Because while curving metal is cool, safety is always cooler.

—

**4. Operating and Safety Procedures for Metal Roofing Sheet Curving Machines**

**Operating Instructions**

When operating a metal roofing sheet curving machine, always follow the manufacturer’s instructions to a T. Make sure you understand how the machine works before diving in, and don’t be afraid to ask for help if needed. Remember, safety and precision go hand in hand.

**Safety Precautions**

Safety goggles? Check. Gloves? Check. Common sense? Double-check. Prioritize safety at all times when working with metal roofing sheet curving machines. Accidents happen, but with the right precautions, you can curve metal sheets like a pro without breaking a sweat.

**Emergency Protocols**

In case of emergencies, know where the emergency stop button is located and how to use it. Familiarize yourself with the machine’s emergency protocols so you can act swiftly and decisively if the unexpected happens. Stay calm, stay safe, and keep on curving those metal sheets like the rockstar you are.

—

Metal roofing sheet curving machines may seem like straightforward tools, but they are instrumental in creating roofs that not only protect but also impress. Whether you prefer the hands-on approach of manual machines or the high-tech wizardry of automated ones, there’s a metal roofing sheet curving machine out there for every project. So go ahead, bend it like Beckham, but with metal sheets instead of soccer balls.

5. Benefits of Using Metal Roofing Sheet Curving Machines

Increased Efficiency

Metal roofing sheet curving machines streamline the curving process, enabling faster production times and increased efficiency in roofing projects.

Precision Curving

With metal roofing sheet curving machines, you can achieve precise and consistent curving results, ensuring a professional finish and optimal functionality for the roof structure.

Cost Savings

By utilizing metal roofing sheet curving machines, you can reduce labor costs, minimize material waste, and enhance overall productivity, leading to significant cost savings in the long run.

6. Maintenance Tips for Metal Roofing Sheet Curving Machines

Regular Inspection and Cleaning

Perform routine inspections and cleaning of your metal roofing sheet curving machine to prevent debris buildup, ensure smooth operation, and prolong the machine’s lifespan.

Lubrication of Moving Parts

Apply lubrication to the moving parts of the curving machine to reduce friction, maintain optimal performance, and prevent wear and tear on essential components.

Repair and Replacement Guidelines

Follow manufacturer guidelines for repair and replacement of worn-out or damaged parts to avoid downtime, maintain efficiency, and prolong the functionality of your metal roofing sheet curving machine.

7. Industry Applications of Metal Roofing Sheet Curving Machines

Construction Sector

Metal roofing sheet curving machines are widely used in the construction industry for creating curved roof structures that enhance architectural aesthetics and improve structural integrity.

Architectural Design Industry

In architectural design, metal roofing sheet curving machines play a crucial role in realizing innovative and complex roof designs, offering architects and designers a versatile tool for creative expression.

Automotive Manufacturing

Metal roofing sheet curving machines find applications in automotive manufacturing for shaping metal components used in vehicle construction, contributing to the production of durable and aerodynamic automotive designs.In conclusion, metal roofing sheet curving machines are indispensable tools for professionals in the construction, architecture, and manufacturing industries. By incorporating the right machine for the job and following proper operating and maintenance procedures, businesses can enhance productivity, ensure safety, and deliver high-quality results. With a deep understanding of these machines and their applications, industry professionals can leverage the power of metal roofing sheet curving technology to meet the demands of modern design and construction projects efficiently and effectively.

FAQs about Metal Roofing Sheet Curving Machines

1. What are the primary benefits of using a metal roofing sheet curving machine?

2. How often should maintenance tasks be performed on a metal roofing sheet curving machine?

3. Can a metal roofing sheet curving machine work with different types of metal sheets?

4. What safety precautions should operators take when using a metal roofing sheet curving machine?

Post time: Mar-12-2024