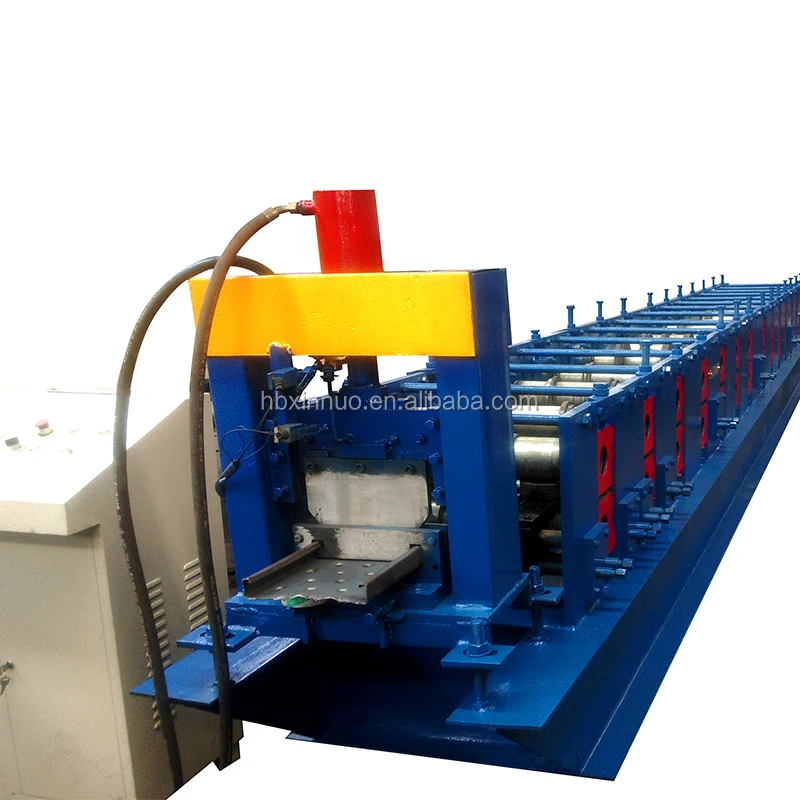

scaffolding walk roll forming machine

| Our machine | Influence of the machine | |

| Main forming

machine body |

High strength H300 or H350 steel.

machine through milling machine after welding |

Sturdy and durable,

ensure the plate standard |

| Material of the

roller |

GCr15 | Ensure the forming effect of

the panel and the use age will be longer,the surface of the panel |

| Material of the

cutting |

Cr12 steel with quenched treatment | Cutting is out of shape not easily

and use age will be longer,the panel size precision |

| Material of the

active shaft |

High grade No.45 forged steel,

Shaft diameter is 80 or 75mm. |

Improve the integrated mechanic

feature of the shaft and keep product standard |

| Control system | PLC control system,some elements are

imported from Japan and Germany |

Machine become more accurate and

more stable |

Terms of Payment: 30% of the total contract value paid by T/T as down payment, the rest 70% of the total contract

value to be paid by T/T after inspection by buyer in seller’s factory while before delivery.

Delivery: 30 days after receipt of advance payment

Service: we send technician to your country to fix the machine.The buyer should bear all the cost including: visa,

Round trip tickets and suitable accommodation, also buyer should pay salary 80USD/day.

Warranty: 12 months limited warranty

During warranty: parts are free but buyer pay for the shipping fee.

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines,

but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail

roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter

slat door forming machines, downpipe machines, gutter machines, etc.

Our machines feature beautiful appearance, long service life, good performance, simple operation, reasonable price,

good quality and so on.

Strong technical resources are the most stable guarantee for our products’ quality. We adopt computer software for

design drawing, production drawing and installation drawing for steel construction equipment. We adopt advanced

computer digital inspection and produce high quality light steel structure equipment. Our technical is updating day

by day!

Our company has matured after sale service network, we could provide efficient and satisfactory service for you

throughout the period of our cooperation.If necessary, we can supply you with local technical support and send

technicians to for installation and operation training.

1:How to play order:

Inquiry—confirm the profile drawings and price—-confirm the PI—arrange the deposit or L/C—then OK

2:How to visit our company:

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3:When we exported the machines:

We have beening making and exporting the machines since from the year of 1998.

4.What’s the after- sale service:

we sent technician to your country to fix the machine.The buyer should bear all the cost including:

visa, round trip ticket and suitable accommodation, also buyer should pay the salary 80USD/day.

5.How about the warranty: 12 months limits warranty

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.