welcome to visit us,

#rollformingmachine #rollforming #sandwichpanel #purlinmaking #xinnuomachine #lightkeel #drywall #steelbuilding,

|

NO.

|

Main parameter of Botou city canton fair authentication 828 automatoc press blue making glazed joists steel roof tile roll froming machine with ce

|

|

|

1

|

Suitable to process

|

Color steel plate

|

|

2

|

Width of the plate

|

1000mm

|

|

3

|

Thickness of the plate

|

0.3-0.7mm

|

|

4

|

De-coiler

|

Manual one, can load 5 tons raw material

|

|

5

|

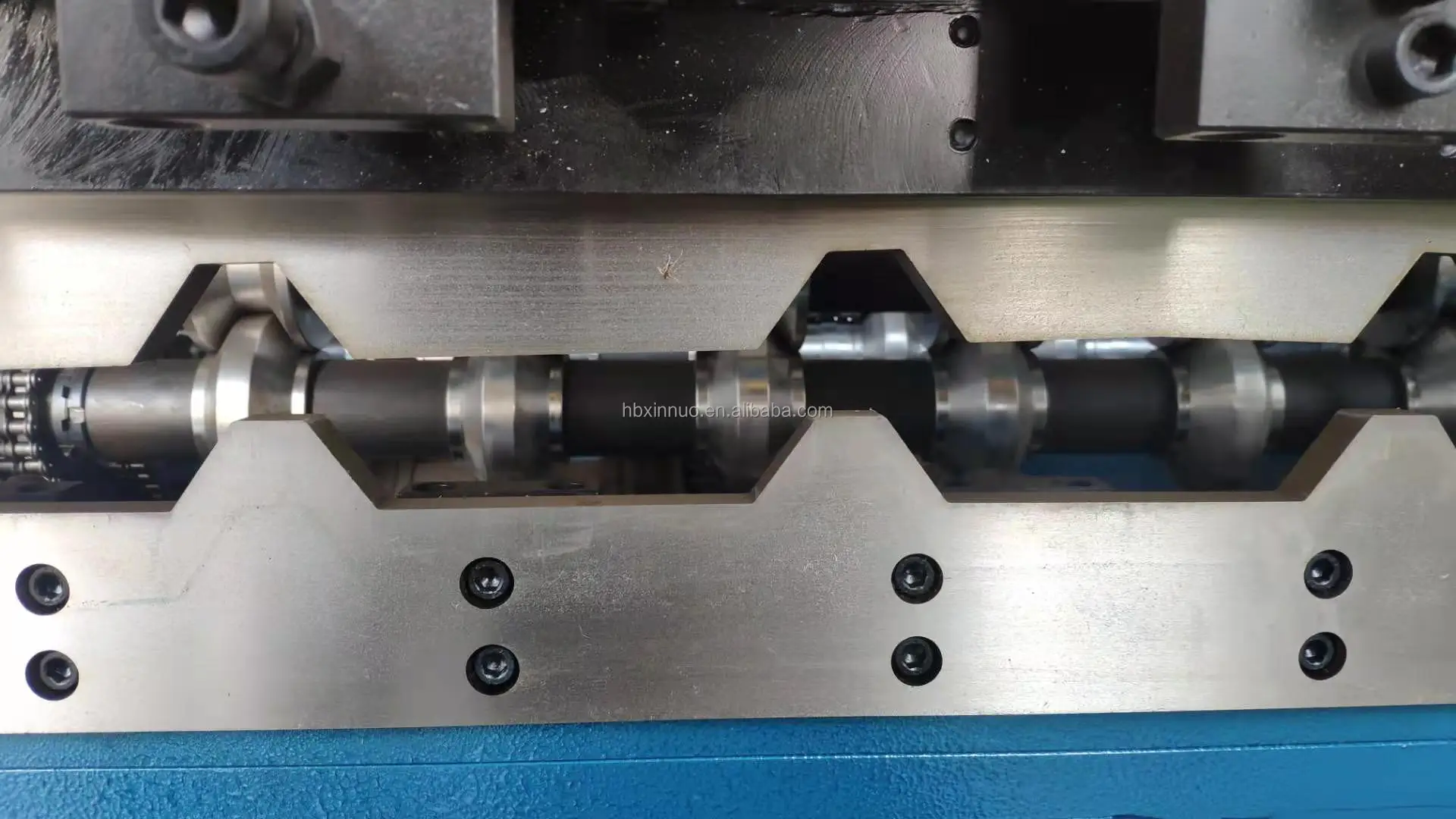

Rollers for forming

|

12 rows

|

|

6

|

Diameter of the roller

|

80mm

|

|

7

|

Rolling material

|

Carbon Steel 45#

|

|

8

|

Main motor power

|

4kw

|

|

9

|

Productivity

|

0-3m/min

|

|

10

|

Cutting method

|

Hydraulic and guide pillar cutting

|

|

11

|

Material of the cutting blade

|

Cr12

|

|

12

|

Hydraulic cutting power

|

3kw

|

|

13

|

Processing precision

|

Within 1.00mm

|

|

14

|

Control system

|

Delta PLC control

|

|

15

|

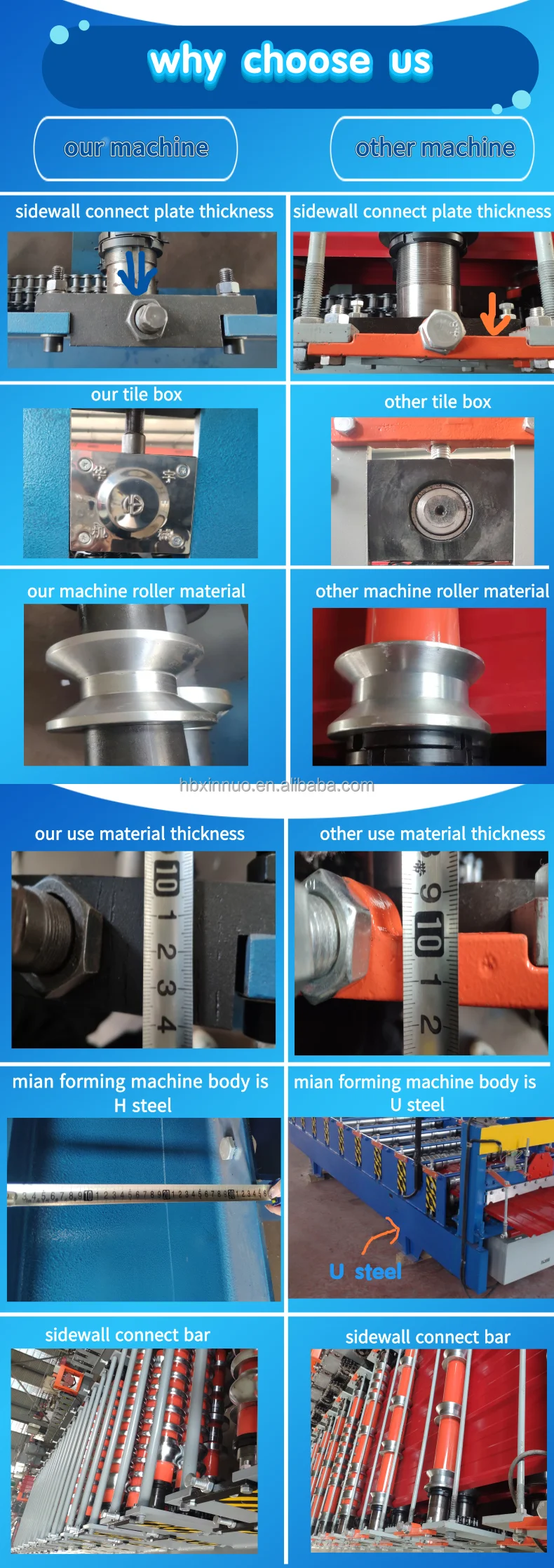

Side panel of machine

|

14mm

|

|

16

|

Main structure of the machine

|

300 H steel

|

|

17

|

Weight

|

About 4.0T

|

|

18

|

Dimensions

|

7.0*1.5*1.55m

|

|

19

|

Voltage

|

380V 50Hz 3phases(changeable as needs)

|

|

20

|

Certificate

|

CE/ISO

|

|

21

|

Custom

|

According to customer’s requirements

|

|

Packaging Details:

|

Main machine is nude, the computer control box is packed with wooden frame.

|

|

Main machine is nude in the container, the computer control box is packed with wooden packaging.

|

|

|

Delivery Detail:

|

20 days

|

We are manufacturers and designers of roll forming machines from China.

Products mainly include

Roof/Wall roll forming machine.

C/Z/U purlin roll forming machine.

EPS/Rock-wool sandwich panel roll forming machine production line.

Light steel frame machines and so on.

Based on 30 years of experience,We can supply you one-stop solution to fulfill all your needs in metal roll forming industry.

What is metal roll forming?

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

Our factory is located in Botou City, Hebei Province, China, close to Beijing.

1,Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick you up.

2,Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick you up.

We offer a one-stop service for all your building materials and machinery needs, saving you time and money.

All our machines come with a range of standard features that ensure safety, functionality, and ease of use are second to none.

Our company attaches great importance to customer reputation and product quality because we know that only high-quality products can create more value for customers.

Contact now and start a new experience!

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

-

High Quality for China Solar Panel Aluminum PV ...

-

Cheap price High Quality Low Cost Truss Light G...

-

Trending Products high output corrugated and gl...

-

China Gold Supplier for Color Steel Cold Roof T...

-

China Factory for Steel Round Downspouts Roll F...

-

Wholesale ODM Top Quality Customized Solar Brac...