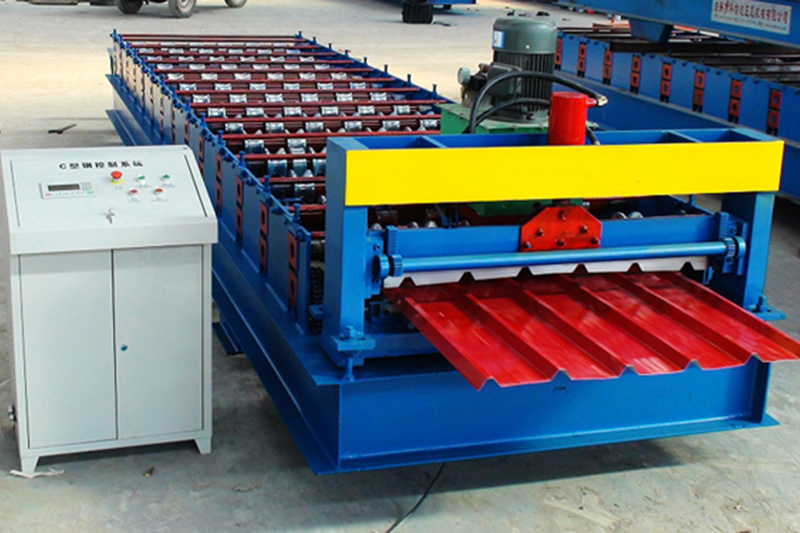

Xinnuo EGA 500/600 Ghana Special Roof Sheet Cold Roll Forming Machine,

Cold Roll Forming Machine, long span, production line., roof sheet, xinnuo machine,

*Detail

Roofing sheet roll forming system is comprised of material feeding, roll forming, and shearing sections. Equipped with PLC computer control system and hydraulic pumping system, the forming machine is of high automation and is easy to be operated.

Xinnuo is able to customize panel roll forming machines used for producing roof panels with different shapes and dimensions according to the standards of different regions. We have 840. 850, and 860 series machines for im-wide panels. For roof panels used in Southeast Asia whose required width is 914mm, we have 760 and 762 series prepared. 1000 series roof panel forming machine is designed for the Middle East where the roof panels are generally 1200mm or 1220mm wide. Customization service is offered by our design team, which is comprised of over 10 professional designers.

This roof panel forming machine is mainly applied in producing roofing panels of plant, warehouse, garage, hangar stadium, exhibition hall, and theaters, etc.

*Features

a. The roof panel roll former is equipped with PLC touch screen control system (multi-language selection system is available upon request)

b. The double-line chain allows for uniform and large transmission force

c. The cutting blades of the roofing sheet roll forming machine is made from Cr12 molybdenum-vanadium steel, featuring high hardness and high wear resistance. The roofing sheet produced by the roll forming machine is distinguished for flat surface

d. Shaft made from 45# steel is designed with a diameter of 80mm

e. 24V constant pressure hydraulic system

f. Shear beam made of 20mm-thick plates

*1000type roll forming machine

| Configurations | Manual Uncoiler ,Guiding Platform ,Coil Strip Leveler ,Main Machine Of Roll Forming ,Electro-Motor,Cutting Device ,Hydraulic Station ,PLC Control, Supporter Table. |

| Control System | PLC Delta Inverter |

| Main Frame | 300mm H-Beam |

| Main Power | 4 kw |

| Pump Power | 3 kw |

| Power Supply | 380V, 3-Phase,50Hz |

| Forming Speed | 15-20m/min |

| Cutting speed | 8-12m/min |

| Roll Station | 14 stands |

| Roller Diameter | 80mm |

| Hydraulic Pressure | 10-12MPa |

| Forming Size | 1000mm |

| Feeding Thickness | 0.3-0.8mm |

| Feeding Width | 1220mm |

| Backboard Thickness | 14mm |

| Chain Size | 20mm |

| Cutter Standard | Cr12 |

| Roller Standard | 45# |

| Cr-Plating Size | 0.05mm |

| Overall Size | 7500×1450×1600mm |

| Total Weight | 4.5T |

All parameters can be customized, we have a high, medium and low version of each machine configuration

*Application

Introducing the Xinnuo EGA 500/600 Ghana Special Roof Sheet Cold Roll Forming Machine – the ultimate solution for your roofing needs. This exceptional machine, part of the Xinnuo machine collection, is specifically designed to produce high-quality, long-span, and durable roof sheets. With its state-of-the-art technology and powerful production line, it guarantees unmatched performance and superior results.

The Xinnuo EGA 500/600 Ghana Special Roof Sheet Cold Roll Forming Machine is designed to make your roofing projects easier, quicker, and more efficient. Crafted with precision and engineering excellence, this machine is tailored to meet the demands of the modern roofing industry. Whether you are a professional contractor or a DIY enthusiast, this machine is perfect for use in any roofing project.

One of the most notable features of this machine is its cold roll forming mechanism. This technology ensures that the roof sheets are formed without the need for excessive heat, making them stronger and more resistant to corrosion. This means that your roof will withstand the test of time, ensuring long-lasting protection for your property.

With its advanced production line, this machine is capable of delivering a high volume of roof sheets in a short period. This not only saves you time but also allows you to meet even the most demanding project deadlines. You can say goodbye to delays and setbacks, as this machine optimizes efficiency and productivity.

In addition to its outstanding performance, the Xinnuo EGA 500/600 Ghana Special Roof Sheet Cold Roll Forming Machine is designed with the customer in mind. We understand that your needs are unique, which is why this machine is incredibly versatile. It can produce a wide range of long-span roof sheets, catering to various architectural styles and preferences. From traditional designs to contemporary aesthetics, this machine has got you covered.

The ease of use and convenience of this machine cannot be overstated. Designed to be user-friendly, it allows both professionals and beginners to operate it effortlessly. Intuitive controls and a clear interface ensure a smooth and seamless experience. Furthermore, its compact design allows for easy transportation and storage, making it suitable for both on-site and off-site projects.

Investing in the Xinnuo EGA 500/600 Ghana Special Roof Sheet Cold Roll Forming Machine means investing in quality, reliability, and longevity. With its exceptional engineering and robust build, this machine is built to endure even the harshest conditions. Rest assured, your roof will remain steadfast in the face of strong winds, heavy rains, and extreme temperatures.

To sum it up, the Xinnuo EGA 500/600 Ghana Special Roof Sheet Cold Roll Forming Machine is the epitome of excellence in roofing technology. Its ability to produce long-span roof sheets, combined with its cold roll forming mechanism and efficient production line, sets it apart from the competition. This machine offers an unparalleled combination of quality, performance, and convenience. Upgrade your roofing game today with Xinnuo and experience the difference.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

-

Factory Price For Ridge Tile Manufacturing Roof...

-

China Supplier 2019 Highway Guardrail Hot DIP G...

-

2024 Hot sale Good Quality Xinnuo CZ purlin Col...

-

High definition Roof Sheet Roll Forming Machine...

-

Factory Price For China FRP Roofing Sheets Maki...

-

OEM Factory for Stone Coated Roof Tile Producti...