Xinnuo Galvanized iron sheet forming machine,

Galvanized iron sheet roll forming machine,

|

NO.

|

Main parameter of Botou city canton fair authentication 828 automatoc press blue making glazed joists steel roof tile roll froming machine with ce

|

|

|

1

|

Suitable to process

|

Color steel plate

|

|

2

|

Width of the plate

|

1000mm

|

|

3

|

Thickness of the plate

|

0.3-0.7mm

|

|

4

|

De-coiler

|

Manual one, can load 5 tons raw material

|

|

5

|

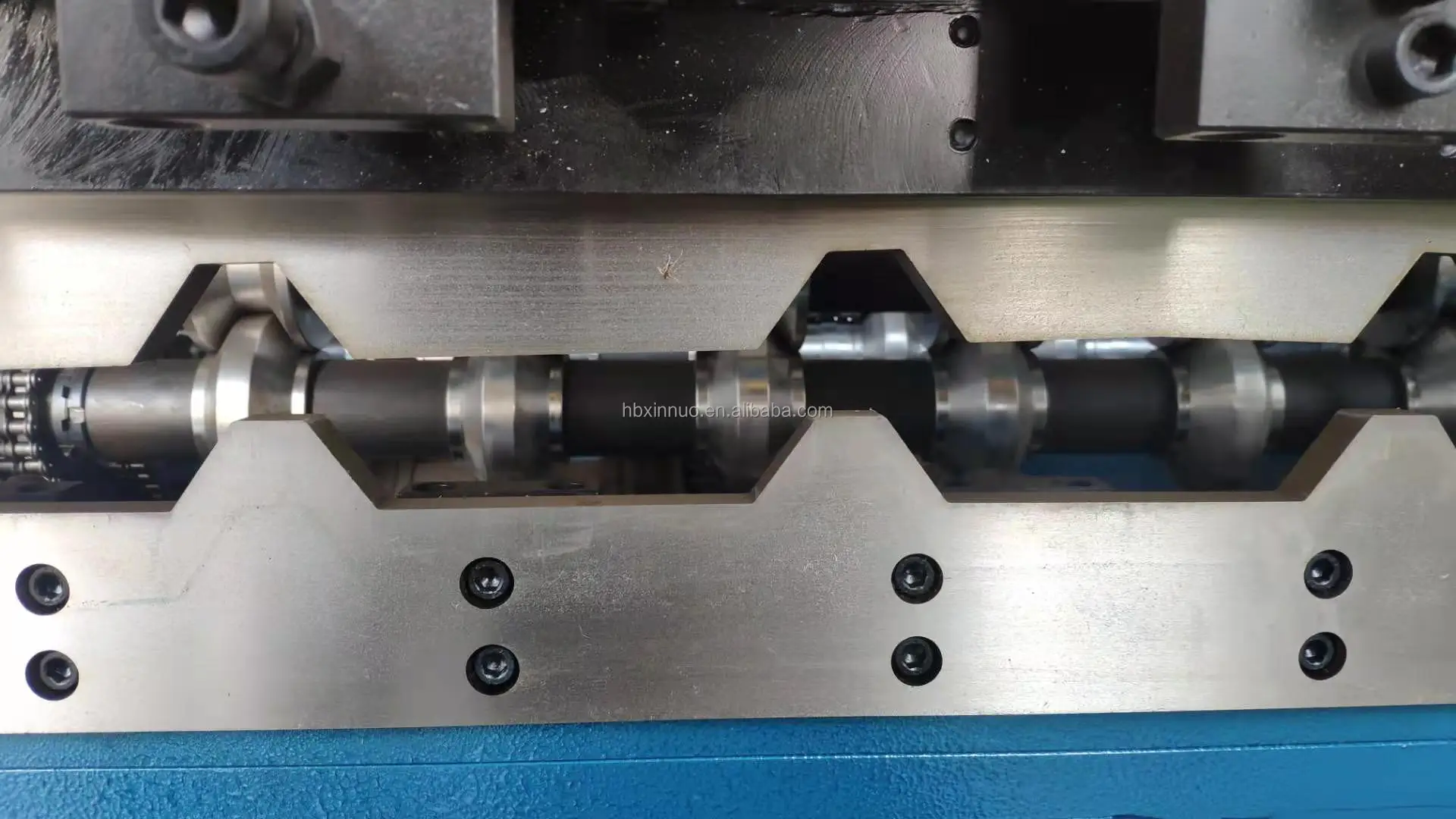

Rollers for forming

|

12 rows

|

|

6

|

Diameter of the roller

|

80mm

|

|

7

|

Rolling material

|

Carbon Steel 45#

|

|

8

|

Main motor power

|

4kw

|

|

9

|

Productivity

|

0-3m/min

|

|

10

|

Cutting method

|

Hydraulic and guide pillar cutting

|

|

11

|

Material of the cutting blade

|

Cr12

|

|

12

|

Hydraulic cutting power

|

3kw

|

|

13

|

Processing precision

|

Within 1.00mm

|

|

14

|

Control system

|

Delta PLC control

|

|

15

|

Side panel of machine

|

14mm

|

|

16

|

Main structure of the machine

|

300 H steel

|

|

17

|

Weight

|

About 4.0T

|

|

18

|

Dimensions

|

7.0*1.5*1.55m

|

|

19

|

Voltage

|

380V 50Hz 3phases(changeable as needs)

|

|

20

|

Certificate

|

CE/ISO

|

|

21

|

Custom

|

According to customer’s requirements

|

|

Packaging Details:

|

Main machine is nude, the computer control box is packed with wooden frame.

|

|

Main machine is nude in the container, the computer control box is packed with wooden packaging.

|

|

|

Delivery Detail:

|

20 days

|

With the continuous development of science and technology, various equipment in industrial production are also constantly updated. Among them, the galvanized iron coil forming machine, as an important production equipment, is widely used in many fields. This article will elaborate on the galvanized iron sheet forming machine.

I. Overview

The galvanized iron coil forming machine is a piece of equipment that processes iron coils into various shapes and specifications. Its working principle is to process the iron sheet into the required shape and size through a series of forming molds and mechanical devices. This kind of equipment is widely used in construction, automobile manufacturing, home appliances and other fields.

2. Working principle

The working principle of the galvanized iron sheet forming machine mainly involves the following steps:

Uncoiling: Place the iron sheet coil on the uncoiling device and send it into the forming area through the traction device.

Forming: In the forming area, the sheet metal coil passes through a series of forming dies and is processed into the required shape and size. The forming mold can be replaced as needed to adapt to different specifications and shapes of iron sheet coils.

Welding: During the forming process, if the iron sheet coils need to be welded together, this can be achieved through a welding device. The welding device can be adjusted as needed to suit different welding requirements.

Galvanizing: After forming and welding, the iron sheet coil can be galvanized to improve its corrosion resistance and service life. The galvanizing device can be adjusted as needed to suit different galvanizing requirements.

Cooling: After completing the galvanizing process, the iron sheet needs to be cooled to stabilize it and improve its quality. The cooling unit can be adjusted as needed to suit different cooling requirements.

Rewinding: Finally, the processed iron sheets are rolled up for subsequent processing or transportation. The winding device can be adjusted as needed to accommodate iron sheet coils of different specifications and sizes.

3. Application fields

As an important production equipment, galvanized iron sheet forming machine is widely used in many fields. Here are some of the main application areas:

Construction field: In the construction field, galvanized iron sheet forming machines are mainly used to manufacture roofs, wall panels and other building materials of various shapes and specifications. Due to its excellent corrosion resistance and good appearance quality, it is widely used in various types of construction projects.

Automobile manufacturing field: In the automobile manufacturing field, galvanized iron sheet forming machines are mainly used to manufacture automobile bodies, doors and other components. Due to its excellent strength and rigidity, it meets the high requirements of automotive manufacturing.

Home appliance business field: In the home appliance business field, galvanized iron sheet forming machines are mainly used to manufacture home appliance casings and parts of various shapes and specifications. Because of its good appearance quality and corrosion resistance, it can meet the requirements of home appliances.

Other fields: In addition to the above fields, galvanized iron sheet forming machines are also widely used in chemical industry, petroleum, light industry and other fields where metal products of various shapes and specifications are required.

4. Conclusion

To sum up, the galvanized iron coil forming machine, as an important production equipment, is widely used in many fields. As technology continues to develop, its performance and quality are also constantly improving. In the future, with changes in market demand and technological advancement, galvanized iron sheet forming machines will continue to play an important role in providing strong support for the production and development of various industries.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

-

Professional China China Unsaturated Resin Fibe...

-

Xinnuo Ridge Cap Roll Forming Machine with Edge

-

OEM Factory for Kexinda Expressway Guardrail Ro...

-

Manufacturer of Automatic New Type Metal High S...

-

PriceList for Converted Container Office/ISO 20...

-

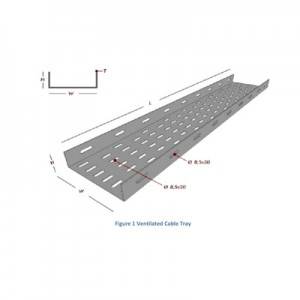

New designed Xinnuo cable tray cold roll formin...